Case studies

We have already manufactured 1 million parts for 500 clients across Poland.

Discover how clients from diverse industries have leveraged industrial 3D printing technology in factories, industrial plants, and companies, revolutionizing the design of innovative devices.

See how our clients utilize 3D printing in practice.

As 3D printing specialists, we are well aware of the potential benefits that this technology can bring to production. However,

Regular deliveries of standardized parts are among the most critical challenges in maintaining factory operations. The Colgate Palmolive Manufacturing case

Injection molding technology is excellent for producing durable plastic parts. However, the challenge arises when the cost of injection molding

Throughout history, inventors have devised ingenious device concepts that couldn’t be realized in their eras. QuinSpin might have faced a

3D printing often emerges as the most sensible solution for highly unconventional ideas. This time, we assisted Red Bull Polska

Specialized medical devices seldom undergo high-volume production, rendering injection technology impractical. The advent of contemporary 3D printing offers a viable

Enclosures for electronics in limited production runs, allowing for potential design modifications in subsequent phases of implementation. In these endeavors,

The world of manufacturing has witnessed a transformative evolution with the advent of 3D printing technology. It’s not just about

Professional design, durability in challenging saltwater conditions, and impeccable part precision. Our project for XO Boats demonstrates that all of

The story of Cortivision’s Photon Cap device demonstrates how modern 3D printing can accelerate the product development and market introduction

The success of every customer is important to us, but it is particularly gratifying when Polish technology conquers foreign markets

Our collaboration with Innovation AG is a perfect example of utilizing advanced additive technologies in both the prototyping and parts

This case is unique as it involves an incredibly close partnership. Unilogo is located just a few meters away, and

Clients

We have assisted over 500 companies.

Schedule a meeting and discover how professional 3D printing can benefit your business.

Reviews

The success of our clients is our driving force.

At the Novartis factory in Warsaw, we implemented 3D printing for the production of individual format parts in our assembly lines and laboratory equipment. After the testing period, we were impressed by the durability of the printed parts. The use of additive technologies significantly helped us reduce spare parts costs and shortened order fulfillment time from several weeks to just a few days.

Tomasz Pałka

Production Head, Novartis

My main problem is that I have too many ideas. Cubic Inch selects the best ones, tests them, and implements them on Unilogo production lines. Additionally, I usually pay less than I expected. 3D printing and HP Multi Jet Fusion technology are like pure magic.

Tomasz Nowacki

President, Unilogo

From my perspective, the implementation of 3D printing technology primarily opens up new opportunities for testing solutions in the part design phase. What used to take us a few weeks to obtain, I now have on my desk in less than a week. This change introduces an entirely different dynamic to our project work and enables us to meet our customers’ expectations more effectively.

Marek Łach

Senior Process Development Engineer, Hoerbiger

If it weren’t for 3D printing, QuinSpin simply wouldn’t have come to life. No other technology would have allowed me to create this project within my budget.

Arek Biały

QuinSpin Founder

The professionalism and dedication of Cubic Inch enabled us to bring our product to market much earlier. Unlike previous suppliers, we felt a genuine partnership approach that was complemented by a deep understanding of the technology and our needs.

Wojciech Broniatowski

CEO Cortivision

It turned out that thanks to MJF technology, we can 3D print parts even with very small threads, eliminating the need for additional assembly. The time savings in situations where there are, for example, 100 such parts, are significant.

Mateusz Berk

CAD Designer, Unilogo

The implementation of our projects without the support of Cubic Inch would be practically impossible. The technology proved to be perfect for us, and the collaboration process was impeccably smooth.

Piotr Gryszczuk

CTO Innovation AG

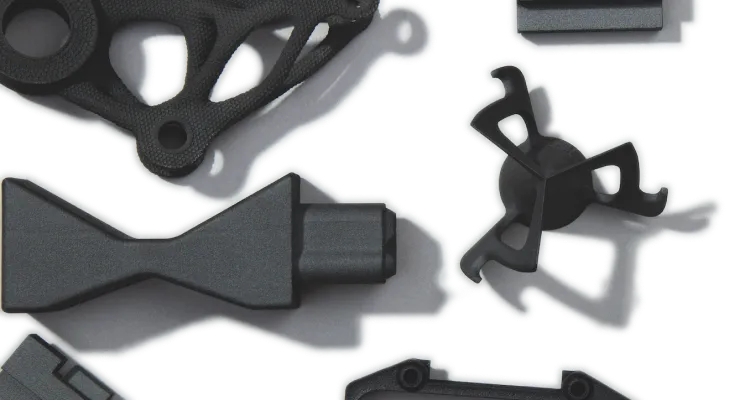

The MJF technology has allowed us, in many cases, not only to streamline processes but also to create entirely new solutions. In some devices, we managed to significantly reduce the number of required parts by using complex geometries. Approximately half of all our machines have been modified by utilizing 3D-printed parts with the Multi Jet Fusion method.

Jarosław Kokot

Technical Director at Imago

Schedule a free 3D printing consultation

Considering implementing 3D printing in your company? Learn about the possibilities and benefits.

Magdalena Pietrasińska

Sales Enginneer