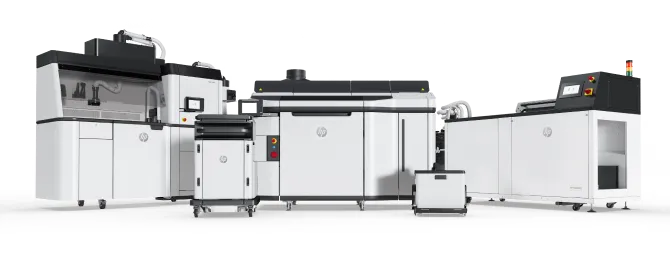

HP Multi Jet Fusion technology

HP Multi Jet Fusion technology is an innovative 3D printing method that allows rapid and accurate manufacturing of durable parts with excellent surface finish.

It is experiencing rapid global expansion and increasingly preferred by businesses as a substitute for injection moulding.

Advantages of the technology

Why is Multi Jet Fusion chosen by numerous companies?

Industrial durability

Consistent dimensions

Enhanced productivity

Complex

designs

Cost-effectiveness

Versatile applications

Smooth surface

A global leader

Multi Jet Fusion's operating principle

See how HP technology works

By utilising polymer powder and an exceptional printing technique, Multi Jet Fusion enables us to attain micron-level precision and reduce production time by a factor of ten compared to conventional methods.

From the idea to the final product in just 3 days

7 steps to 3D printing:

Schedule a free 3D printing consultation

Considering implementing 3D printing in your company? Learn about the possibilities and benefits.

Magdalena Pietrasińska

Sales Enginneer

Applications

Examples of 3D printing applications:

Witness the utilisation of 3D printing by diverse factories and companies in the production of novel devices and even prostheses.

Technical

specification

Multi Jet Fusion

Standard lead time

3-5 days

Dimensional accuracy

+/-0.3mm ≤ 100mm

+/-0.3% >100mm

Layer thickness

80 microns

Minimum wall thickness

1 mm

Maximum build dimensions

380 x 284 x 380 mm

The material used in printing

Poliamid PA12

Part density

1.01 g/cm3

standard ASTM D792

Tensile strength - XY

48 MPa/6960 psi

standard ASTM D638

Tensile strength - Z

48 MPa/6960 psi

standard ASTM D638

Tensile modulus - XY

1700 MPa/245 ksi

standard ASTM D638

Tensile modulus - Z

1800 MPa/260 ksi

standard ASTM D638

Elongation at break - XY

20%

standard ASTM D638

Elongation at break - Z

15%

standard ASTM D638

Heat deflection temperature 1

Heat deflection temperature 2

175°C

95°C

standard ASTM D648

@ 0.45 MPa

@ 1.82 MPa

The range of finish options

See how your parts can be finished

Sanding with graphite

Sanding without graphite

Polyshot surfacing

Vapor fusing

Dyeing

Thread inserts

FAQ

Our experts provide insights and answers to common questions regarding HP's Multi Jet Fusion (MJF) technology, recognized as the fastest-growing additive manufacturing method globally.

Practical Insights into Additive Manufacturing