Just-in-time contract manufacturing

- Cubic Inch virtual warehouse

- Quick part ordering process

- Full implementation and project support

3D Printing - contract manufacturing

What does cooperation with Cubic Inch look like?

02

3D model optimization

Our team of 3D printing engineers introduces corrections that can improve the durability of your parts and even reduce their cost

03

Valuation and schedule

You will receive a customized valuation of the parts and a delivery schedule tailored precisely to meet your requirements.

04

Modifications and new projects

You can enter new projects into the system, on an ongoing basis, and commission us to modify the existing ones.

3D Printing or mould injection?

HP Multi Jet Fusion devices ensure a comparable quality of parts to injection moulding technology, so the price remains the deciding factor, which depends on the geometry of the components, their size, and the volume ordered. The geometric complexity of the design favours 3D printing in this respect, and the large size of parts favours the use of injection moulding technology.

The graph on the right shows the relationship between the number of parts produced and their unit cost in both technologies.

Here are the key advantages of 3D printing over injection moulding technology:

- No initial costs

- Fast implementation

- Greater geometric capabilities

- Possibility to freely change the design between series

3D print technology

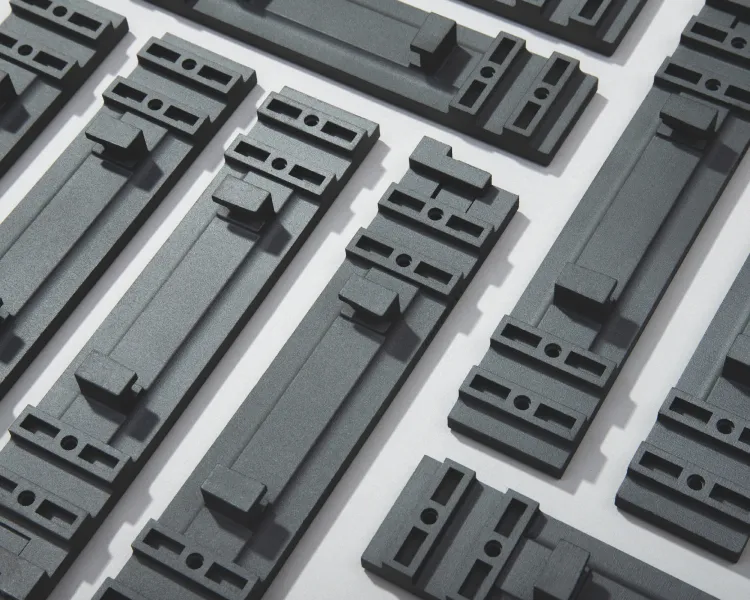

Why Multi Jet Fusion from HP?

Industrial strength

Cost reduction

Short execution time

Who uses the service most often?

- Machine and equipment manufacturers

- Startups

- Factories

Experience of Cubic Inch

We have already printed over 1 million parts

98% of orders are delivered on time

We focus on maximum accuracy in terms of the quality of created parts and timeliness of orders fulfilled.

9 years of experience in 3D printing

We have helped over 500 companies of various sizes and from various industries. We respond to the needs of both large factories, as well as startups and specialised companies.

The most modern technology on the market

We use HP Multi Jet Fusion technology, which guarantees high accuracy and durability of print.

Schedule a free 3D printing consultation

Considering implementing 3D printing in your company? Learn about the possibilities and benefits.

Magdalena Pietrasińska

Sales Enginneer

Resources

Discover more about the concept of just-in-time production.

Process optimization is a concept that has been permanently introduced into the everyday vocabulary of managers and engineers, regardless of…

“The parts that we need can’t be printed in 3D” “3D printing will not work for us. It doesn’t meet…

Every year, more and more press articles and scientific publications discuss the important role of 3D printing in the context…

Process optimization is a concept that has been permanently introduced into the everyday vocabulary of managers and engineers, regardless of…

“The parts that we need can’t be printed in 3D” “3D printing will not work for us. It doesn’t meet…

Every year, more and more press articles and scientific publications discuss the important role of 3D printing in the context…

FAQ

Nasi specjaliści odpowiadają na najczęściej zadawane pytania z zakresu szybkiej produkcji kontraktowej.

Nasze usługi

Practical Insights into Additive Manufacturing