Formatting part for rotating corks on the production line for Avon

As 3D printing specialists, we are well aware of the potential benefits that this technology can bring to production. However, there are situations when even we are amazed at the significant difference this solution can make. The project for Avon’s factory is precisely such a case.

Tool for Enhancing Car Body Painting Process

Regular deliveries of standardized parts are among the most critical challenges in maintaining factory operations. The Colgate Palmolive Manufacturing case illustrates the immense assistance that 3D printing can provide in this area.

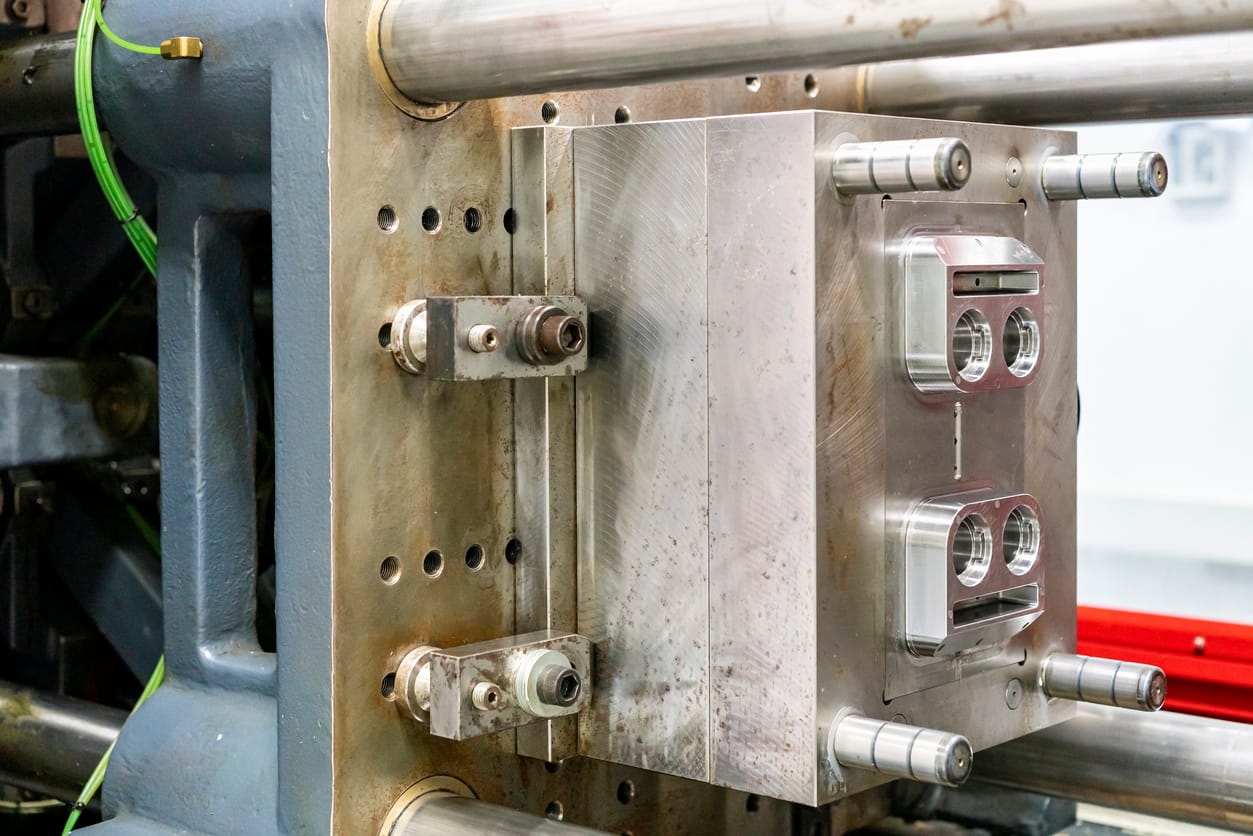

Parking Sensor Housings

Injection molding technology is excellent for producing durable plastic parts. However, the challenge arises when the cost of injection molding tools can reach several hundred thousand zlotys. So, what can be done when only a few hundred parts are needed? The following case study provides an answer to this question.

Coffee Machine Filter Cleaning Device for QuinSpin

Throughout history, inventors have devised ingenious device concepts that couldn’t be realized in their eras. QuinSpin might have faced a similar scenario if not for modern 3D printing.

Spare Parts for Production Lines for Colgate Palmolive Manufacturing

About project Comapny Colgate Palmolive Manufacturing Industry FMCG factory Technology HP Multi Jet Fusion Material Poliamid PA12 Quantity from 1 up 100 in a single batch Lead time 5 dni roboczych dla pojedynczego zamówienia Service Produkcja kontraktowa Projektowanie 3D Doradztwo wdrożeniowe Colgate Palmolive Manufacturing Poland produces toothpaste and mouthwash liquids distributed to various European countries. […]

Custom Climbing Grip for Red Bull

3D printing often emerges as the most sensible solution for highly unconventional ideas. This time, we assisted Red Bull Polska in realizing an extraordinary race…

Revolutionizing Medical Device Manufacturing: HP Multi Jet Fusion at Berger and Kraft

Specialized medical devices seldom undergo high-volume production, rendering injection technology impractical. The advent of contemporary 3D printing offers a viable avenue for the development of such equipment, overcoming the limitations of traditional manufacturing methods.

Electronic Device Casings for Operon

Enclosures for electronics in limited production runs, allowing for potential design modifications in subsequent phases of implementation. In these endeavors, leveraging both 3D printing and HP Multi Jet Fusion technology emerges as an optimal resolution. Within this undertaking, Cubic Inch assumed responsibility for the complete implementation lifecycle, spanning from initial design to the eventual delivery of the meticulously crafted enclosures.

Lower Limb Prosthetic Sockets for Proteo

The world of manufacturing has witnessed a transformative evolution with the advent of 3D printing technology. It’s not just about creating prototypes or small-scale parts anymore; it’s about crafting highly specialized devices and even prosthetics, as demonstrated in this enlightening case study.

Ventilation Grilles for XO Boats

Professional design, durability in challenging saltwater conditions, and impeccable part precision. Our project for XO Boats demonstrates that all of this is achievable using HP Multi Jet Fusion 3D printing technology.