Enclosure manufacturing

We help companies create new devices by supplying high-quality plastic enclosures. We ensure a fast process and no initial costs with modern incremental technologies.

- Cost-effective alternative to injection moulding

- Comprehensive support from 3D production engineers

3D printing - Manufacturing of plastic enclosures

To what extent do you need support?

3D printing - enclosure manufacturing

What is the ordering and manufacturing process for an enclosure?

01

Meeting

We discuss the concept and requirements of the project and the estimated order volumes.

02

Quotation and project schedule

We prepare a quotation and a detailed collaboration and delivery schedule.

03

Design and prototyping

We prepare prototypes and refine them based on your guidelines in successive upgrades. This stage lasts from a week to a month.

04

Just-in-time production

The final version of the project goes to print. Orders arrive at your chosen dates and in the quantities you need.

05

Continuous project improvement

With 3D printing technology, you can continuously improve your design based on user feedback at no extra cost.

Advantages of working with Cubic Inch

Why Choose 3D Printing?

Zero initial costs – you only pay for the parts you order

Significantly reduced implementation time (up to 3 days from project approval)

No need to store parts (orders from 1 pc.)

Possibility of continuous project modifications

See what your parts can look like

Finishes for the Multi Jet Fusion

Sanding without graphite

Parts after printing are only sanded with glass beads. The parts are in their natural color in which they were printed.

Light gray, matte

Polyshot

Additional finishing cost +30%

The parts are sanded without graphite, then dip-dyed black and sandblasted once more with a special medium that imparts a shine.

- Scratch-resistant surface

Black, semi-matte

Vaporfuse (chemical processing)

Additional finishing cost +50%

The parts are sanded without graphite, then dip dyed black. The final gloss is obtained by placing the parts in a chamber with solvent fumes, which overmelt the surfaces.

- Scratch-resistant surface

- Closed surface

- Better mechanical properties

Black, glossy

When Is 3D Printing Cost-Effective?

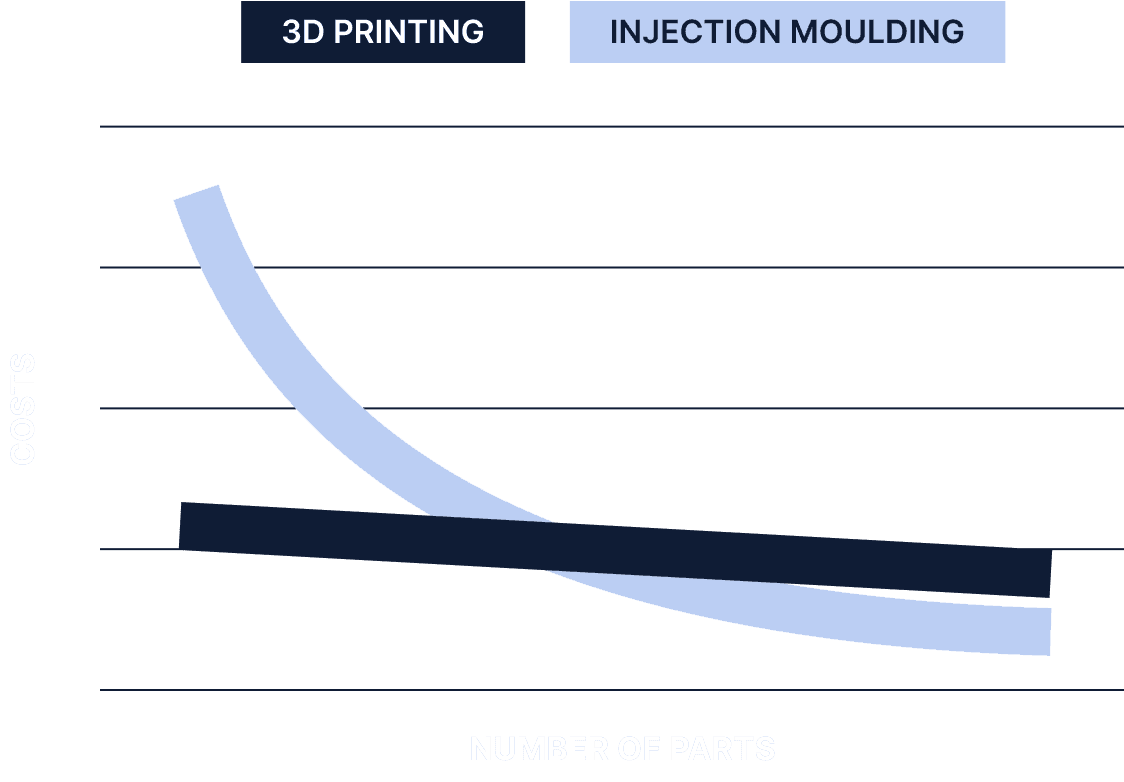

HP Multi Jet Fusion devices offer comparable part quality to injection molding, so the deciding factor remains the cost, which depends on the geometry, size, and ordered volume of the components. Geometric complexity of the project significantly favors 3D printing in this regard, while larger part sizes lean towards injection molding.

- No Initial Costs: 3D printing eliminates the need for costly molds.

- Rapid Turnaround: It offers fast production turnaround times.

- Greater Geometric Flexibility: 3D printing excels at handling complex designs.

- Design Flexibility Between Batches: You can make project changes between production runs.

Our projects

The enclosures for these devices were created using our 3D printers

Zobacz efekty naszej pracy! Wyprodukowaliśmy setki obudów do elektroniki dla naszych klientów.

3D Design / Contract Manufacturing / Device Manufacturing / Enclosures

Contract Manufacturing / Device Manufacturing / Enclosures / Medical devices

3D Design / Contract Manufacturing / Device Manufacturing / Enclosures

Device Manufacturing / Enclosures / Medical devices / Rapid Prototyping / Short-Run Production

3D Design / Enclosures / Factories / Short-Run Production

Contract Manufacturing / Enclosures

Make an appointment for a free online consultation

- After submitting the form, we will contact you to schedule an appointment.

- Application of 3D printing in your project

- Talking to an engineer

- Possibility to order sample prints

Resources

We share expertise on 3D printing using synthetic materials.

Contract Manufacturing / Device Manufacturing / Startups

3D Design / Contract Manufacturing / Factories / Implementation Advisory / Production Parts

3D Design / Enclosures / Factories / Short-Run Production

Device Manufacturing / Enclosures

Custom Products / Enclosures / Short-Run Production

3D Design / Contract Manufacturing / Device Manufacturing / Enclosures

Contract Manufacturing / Device Manufacturing / Enclosures / Medical devices

3D Design / Contract Manufacturing / Device Manufacturing / Enclosures

Device Manufacturing / Enclosures / Medical devices / Rapid Prototyping / Short-Run Production

FAQ

Our experts address the most common inquiries about additive manufacturing for electronic casing production.

Our servives

Expanding Your Company's Potential

Newsletter - Discover the potential of 3D printing