Requirements for customers regarding the project sent for printing

To receive a quick quote from us for printing parts, you can send your design and the number of parts you need. It’s that simple.

Then, the project goes to our 3D printing experts, who determine whether it can be immediately sent to production or whether changes will be recommended that may, for example, reduce the cost of the order.

In this article, we will describe what requirements the project sent to us for printing must meet and what any changes may involve.

File format required for printing

The basic requirement is the file format. Acceptable formats that enable quick pricing are:

- STP

- STL

- OBJ

In the case of technical designs sent in such formats, we can quickly determine whether a given part is ready for printing or requires changes.

An exception worth mentioning is models or sculptures, which are often not designed in parametric software, and we may not be able to print them.

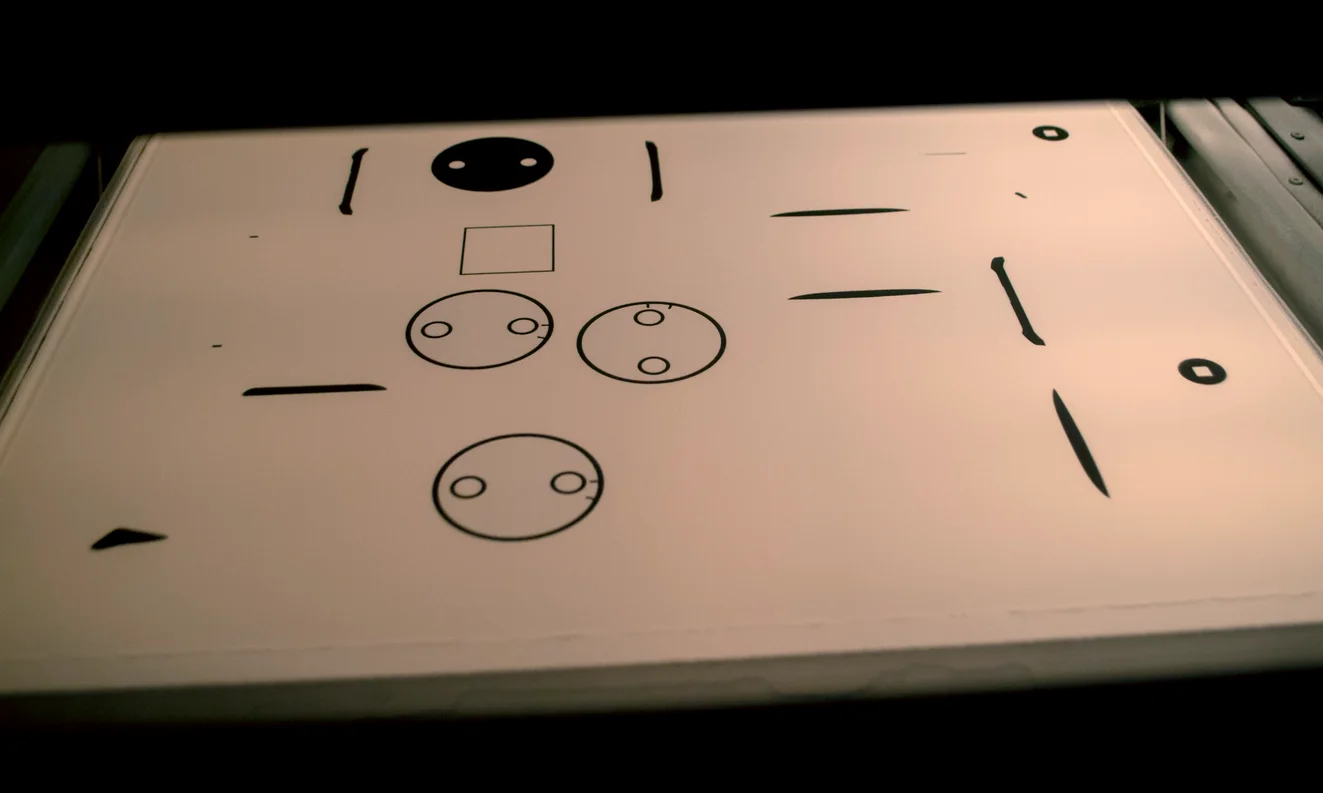

Impact of HP MJF technology on design issues

The technology we use is Multi Jet Fusion, which was created by HP. Those large devices were designed for short-series production and use in production and industry. The process is based on sintering powder from PA12 material, and one of the unique features is that it does not require platforms because the parts are created “in the air.”

MJF provides much higher quality and precision than, for example, FDM printers, as well as the same durability on each axis. Thanks to these advantages, the solution is often chosen as a transitional technology used before investing in an injection mold.

Moreover, due to technological similarities, designs created for injection technology will, in most cases, be immediately ready for printing in MJF technology as long as the wall thickness is at least 0.8 mm.

In the case of projects created previously, e.g. for FDM, it is often possible to introduce additional improvements, allowing for slimmer walls and lighter parts, which can significantly reduce the final valuation.

It is worth keeping in mind the accuracy of HP Multi Jet Fusion technology at the level of +/-0.3mm ≤ 100 mm, +/-0.3% >100mm.

Installation of inserts

If the design is to include inserts, we will need accurate information to precisely adjust the design before printing. Additionally, we need to know whether they are to be installed at our place or someplace else. Documentation and a CAD model will also be very useful.

Each time, we can provide full support and advice on how to solve the issue of inserts so that the holes and assembly system are adjusted to market standards. It may also be necessary to make measurements, which involves additional costs.

Support in the design process

As 3D printing experts with extensive experience in industrial, production, and specialized projects, we support clients in the design process.

We help clients both create from scratch and adapt designs for 3D printing. In the case of factories, we help determine what parts can be replaced with 3D-printed ones and what savings this will bring.

3D scanning and reverse engineering

If you do not have a design but you have a part pattern, you can send it to us. Using the scanner and our designers’ experience, we will create a design based on your pattern. The accuracy of the scan is 0.1 mm, and the scanned items must be between 3 cm and 3 m in size. If necessary, travel to the customer’s location is possible.

The cost of the service depends on the dimensions of the part and its degree of geometric complexity. The minimum price of the service is PLN 500 net.

If you need additional support or have questions for us, contact us or simply send the project for a quote 🙂