As someone who specializes in technology, you undoubtedly spend some of your time researching new solutions that will allow you to implement your projects cheaper, better, and faster.

If you work in a manufacturing company, a startup, or on any project that requires high-quality plastic parts, there is a chance that modern 3D printing has come on your radar during your search.

However, as our conversations with clients often show, implementation may not be that easy. Unfortunately, the problem is that not everyone keeps up to date with the latest solutions and analyzes their potential in the context of company processes.

And of course, not everyone has to.

This is what specialists are for: to properly present the potential benefits and convince management staff and finance specialists.

So let’s talk about the most effective arguments that can help you in conversations with decision-makers.

What do companies gain by using modern 3D printing?

Before we move on to specific arguments, examples of application, and benefits of using 3D printing, we must briefly explain the difference between industrial 3D printers and the commonly known, small FDM (Fused Deposition-Modeling) printers.

Speaking of industrial 3D printing, we are talking primarily about Multi Jet Fusion, a technology created by HP in 2016. These devices are much larger than desktop 3D printers; they are based on a completely different method of making elements and are able to produce up to several hundred parts at a time.

These large printers were created for use in the production of high-quality plastic components, while FDM printers are primarily used for prototyping and printing single components.

So when it comes to issues such as durability, aesthetics, and precision, HP Multi Jet Fusion printers significantly outperform their older and much smaller ancestors based on FDM technology.

In many cases, the reluctance to use 3D printing results from the lack of knowledge about this type of solution and the understanding of 3D printing through the prism of FDM technology. As we often find out in conversations with clients, many concerns about 3D printing stem from previous experience with FDM technology.

We can divide them into 3 main categories.

- Technological – any doubts about the solution itself, the quality of the parts, precision, and whether a specific project can be implemented using this technology. In some cases, they may include supply chain security issues and concerns about supply shortages/delays.

- Process-related – this category includes all types of resistance related to the implementation of a new supplier and new technology into processes in the company. They may concern complex corporate procedures, the reluctance of superiors, security issues, or the potential time required for implementation.

- Cost-related – these concerns may include, among others: issues such as MOQ (Minimum Order Quantity), cost per item, or possible costs of changing the design.

In the following section, we will explain each concern and how much it has to do with reality. As it quickly turns out, the vast majority of them are immediately dispelled by industrial 3D printing.

How much can you save on 3D printing?

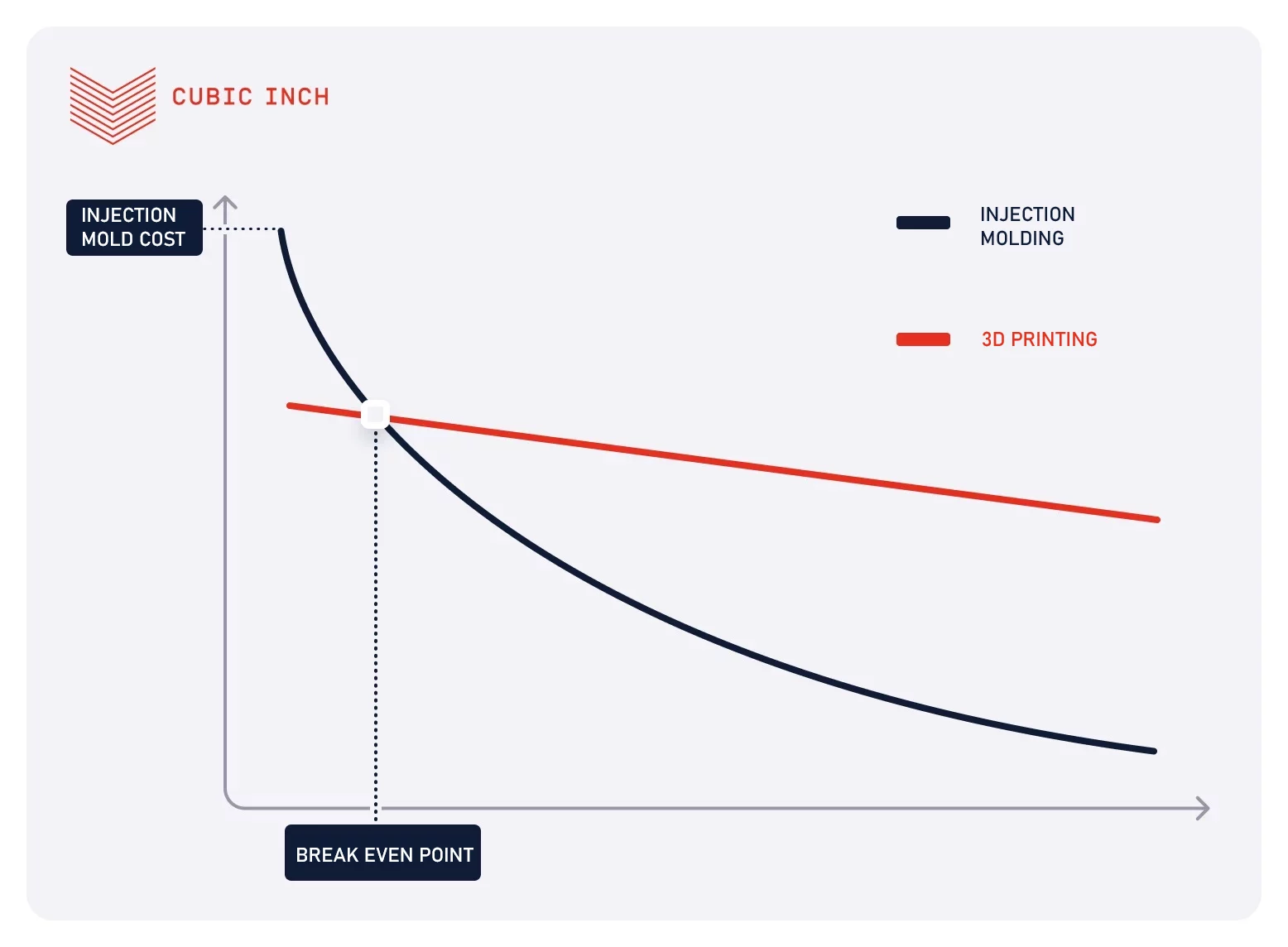

3D printing in MJF technology is perfectly adapted to the production of short and medium series plastic parts. It allows companies to save up to hundreds of thousands of dollars compared to injection molding, which becomes profitable only with much larger volumes.

Threshold profitability is perfectly illustrated by the chart below:

This is because MJF does not require very expensive injection molds and other start-up costs. This means there is no minimum order quantity (MOQ – Minimum Order Quantity), which makes production profitable from just 1 piece. The only thing needed to produce the part is a 3D design.

Moreover, the cost reduction is also reflected in huge savings in working time and real waiting time for the order and production of the mold. The entire process can take up to over 2 months, while the waiting time for 3D printed parts is 3-5 business days.

Finally, additional cost optimization opportunities can also be obtained by introducing changes to designs that are only possible in powder 3D printing technologies. What might they be based on?

- Reduction of the number of components – the ability to combine many elements into one, which reduces assembly and storage costs.

- Geometry optimization – use of trusses that reduce the weight of parts while maintaining high strength.

Technological issues also result in another extremely important advantage of MJF technology from the financial point of view. Due to the lack of MOQ problems and the possibility of any changes in projects, companies using our service gain great flexibility and improve financial liquidity.

Thanks to MJF, you can produce exactly as many pieces as you need, without having to freeze capital in large warehouse batches – in line with the assumptions of JIT (just-in-time manufacturing). This also means the ability to quickly iterate and adapt the design to new requirements without incurring the costs of new molds.

Technological advantages of modern 3D printing

Another common cause of concern is whether 3D printing is able to deliver in terms of quality, durability, or aesthetic values. Also, in this case, it is due to imperfect FDM technology.

In the case of MJF powder 3D printing, however, the situation is completely different. The first MJF printers appeared on the market only in 2016 and immediately gave a clear signal about a completely new standard in additive technologies.

HP MJF printers offer much higher precision and surface uniformity compared to FDM. This makes it possible to create complex, functional parts with tolerances and strength similar to injection methods.

There are also doubts about the design issues themselves and whether specific parts are possible to create. Interestingly, it often turns out that designs are not only possible, but can also be further optimized and made smaller, thereby reducing the production cost.

We describe more about this in the article:

From traditional methods to HP Multi Jet Fusion – optimization of designs for 3D printing

However, the best proof of the effectiveness of the technology is the projects themselves, especially those that require high precision, quality, or aesthetics – e.g., casings or parts of complex electronic devices.

Here are two interesting projects that prove this:

Housing for brain activity testing devices for Cortivision

Housing for a localization device for Taxus IT

It is also worth mentioning that MJF technology is still young and developing very quickly. There are more and more materials from which parts can be printed, new finishing methods, and the process itself is becoming faster, more efficient, and more accurate.

3D printing as a method of optimizing processes and increasing company security

Concerns about the process of implementing new technology into your company are not as common, but they can still play a role, and it is worth being prepared for any questions, such as:

- How long will it take?

- What does the ordering process look like?

- How to convince management staff to dissolve?

- And many similar issues that may result from, for example, complex corporate procedures.

The answer to this question, contrary to appearances, also largely depends on technological possibilities.

Due to the lack of initial costs, you can order samples that can be tested and thus demonstrate the value of the solution. Additionally, the implementation time is only 3-5 business days, so we are not talking about a long and complex process here.

This scenario is very common. In fact, many of our long-term clients started cooperation this way. A good example of such a story is Unilogo, a Polish manufacturer of equipment used in production. First, the company started with small orders, and now parts printed with us are an invariable part of almost every project. You can read about the history of cooperation in case study.

Immediate benefits of industrial 3D printing

When listing the benefits of 3D printing, we must talk not only about the numbers or aspects related to process optimization, but also about the fact that they are visible right away.

The introduction of industrial 3D printing by company brings the following advantages:

- Limiting the time and financial risk associated with investing in an injection mold.

- Improving cash flow through just-in-time orders

- Shortening the process of product development and implementation on the market

- Expansion of the possibilities in terms of product and offer development thanks to the use of modern technology.

However, if the above article didn’t answer all your (or your team’s) questions, we’ll be happy to help you with any other questions you may have.

Make an appointment for a free consultation, and together we will consider what modern 3D printing can bring to your company.