Comapny

Imago Printers

Industry

Industrial automation

Technology

Material

Quantity

Short series ranging from one to several units

Lead time

3-5 work days

Service

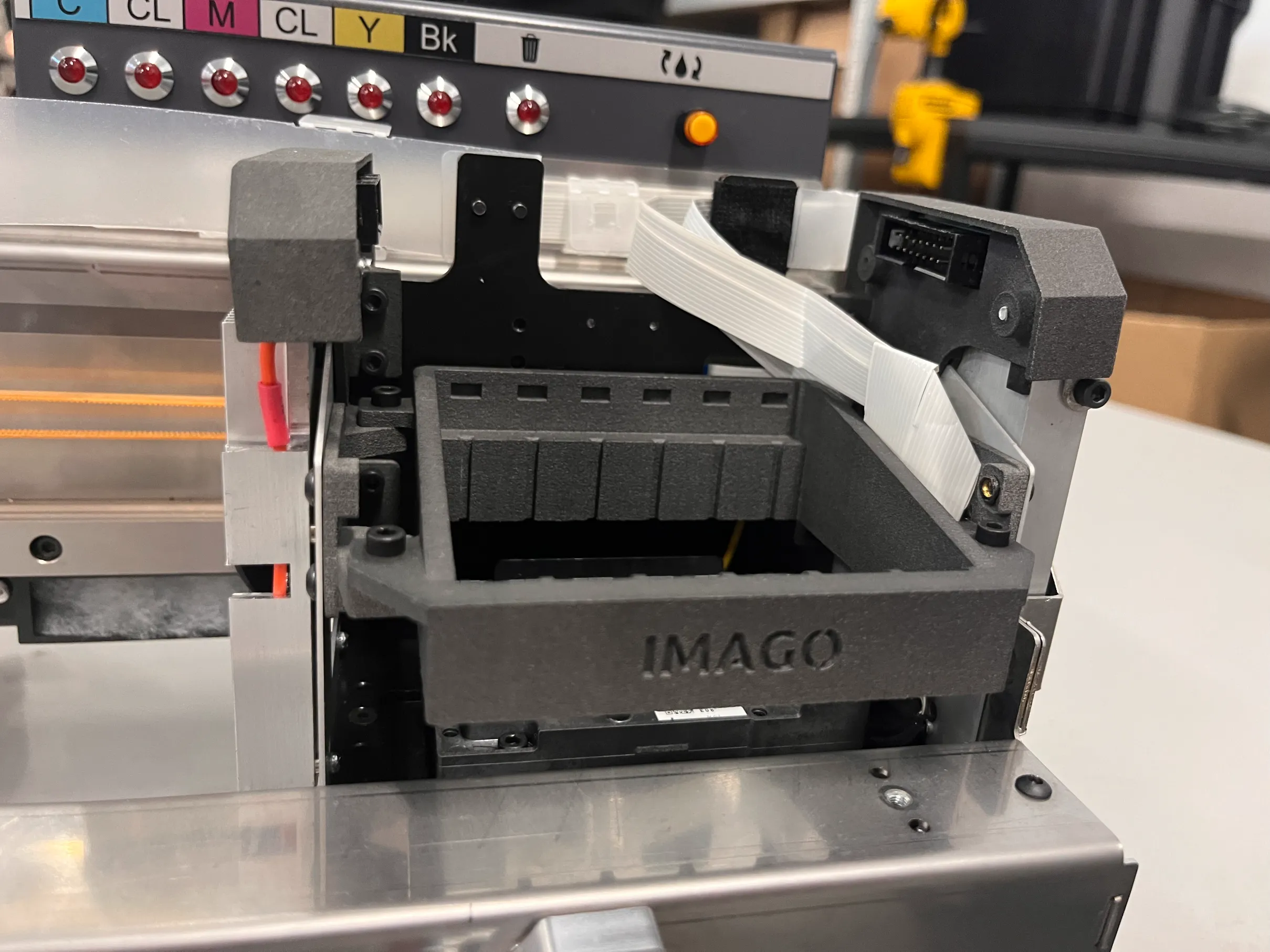

Imago is a manufacturer of specialized printers for professional and production applications. The company fully represents Polish technological thinking. The devices are entirely designed and manufactured by a team of engineers and designers in Warsaw.

Although the company has only been in existence since 2019, it has managed to establish a dominant position by creating innovative solutions, such as confectionery printers, which have completely dominated the Polish market.

We had worked with companies that provided 3D printed parts using FDM technology before, but they fell far short of our quality requirements. We also lacked an engineering approach in those collaborations, and we didn’t feel that our problems were understood by the suppliers.

Technical Director, Imago

Specialized printers produced by Imago are created in short series and, in exceptional cases, require individual modifications. Each such printer requires approximately 50 parts that must meet high standards of durability and aesthetics. At the same time, due to the low volume of orders, creating these parts using injection molding or pressure casting would be entirely unprofitable.

Initially, the Imago team was skeptical about 3D printing. Jarosław Kokot, Imago’s Technical Manager, recalls his experience with additive technologies:

“We had worked with companies that provided 3D printed parts using FDM technology before, but they fell far short of our quality requirements. We also lacked an engineering approach in those collaborations, and we didn’t feel that our problems were understood by the suppliers.”

After the initial discussions with the Imago team, we knew that with our approach and HP Multi Jet Fusion (MJF) technology, we would be able to solve their problems.

The first order for Imago was a significant test that allowed us to quickly demonstrate the capabilities and quality that 3D Multi Jet Fusion printing technology can provide. It involved a dust extraction part that had to fit within a 20 mm space. The part had a complex geometry, but it posed no problem for our printers. The delivered part made a big impression on the Imago team, and the collaboration began in earnest.

Shortly after the first project was delivered, it became clear to the Imago team that MJF technology provides a completely different quality and design possibilities than the solutions the client had encountered before. During our collaboration, we provided support to the client’s engineers and designers for further improvements and modifications that could further facilitate the production process or reduce the cost of parts.

In many cases, MJF technology allowed us not only to improve the process but also to create entirely new solutions. We managed to significantly reduce the number of required parts using complex geometries in some devices. Approximately half of all our machines were modified using 3D printed parts with the Multi Jet Fusion method.

-Jarosław Kokot, Technical Director

With each month of collaboration, the Imago team became more familiar with the possibilities of additive technology, which does not require supports. Imago’s designers began to design elements that allowed for the elimination of additional calibrations, compressions, and facilitated further assembly.

Currently, Imago orders approximately 500 parts from us each month. We have become one of the main suppliers of parts, and Imago’s engineers are already designing and improving devices with Multi Jet Fusion technology in mind.

HP Multi Jet Fusion technology has significantly reduced the production costs of most Imago devices.

The quality and freedom in designing complex geometries have allowed the Imago team not only to improve their projects but also to realize ideas that were previously considered impossible.

The client's team received expert support in implementing 3D technology into the company's processes and receives ongoing guidance regarding ordered projects.

A stable lead time of 3-5 business days has allowed Imago to better plan processes and accelerate device production.

Write to us and quickly quote for the implementation of your project using 3D printing.