Schedule a free consultation with our engineer and order sample parts.

Schedule a free consultation

Schedule a free consultation with our engineer and order sample parts.

Schedule a free consultation

Comapny

Unilogo Robotics

Industry

Industrial automation

Technology

Material

Quantity

from 1 up to 30 pcs. in a single batch

Lead time

3-5 days

Service

Unilogo manufactures modern equipment for the manufacturing industry, including fillers, labelers, and entire production lines tailored to the specific needs of clients, in line with Industry 4.0 principles.

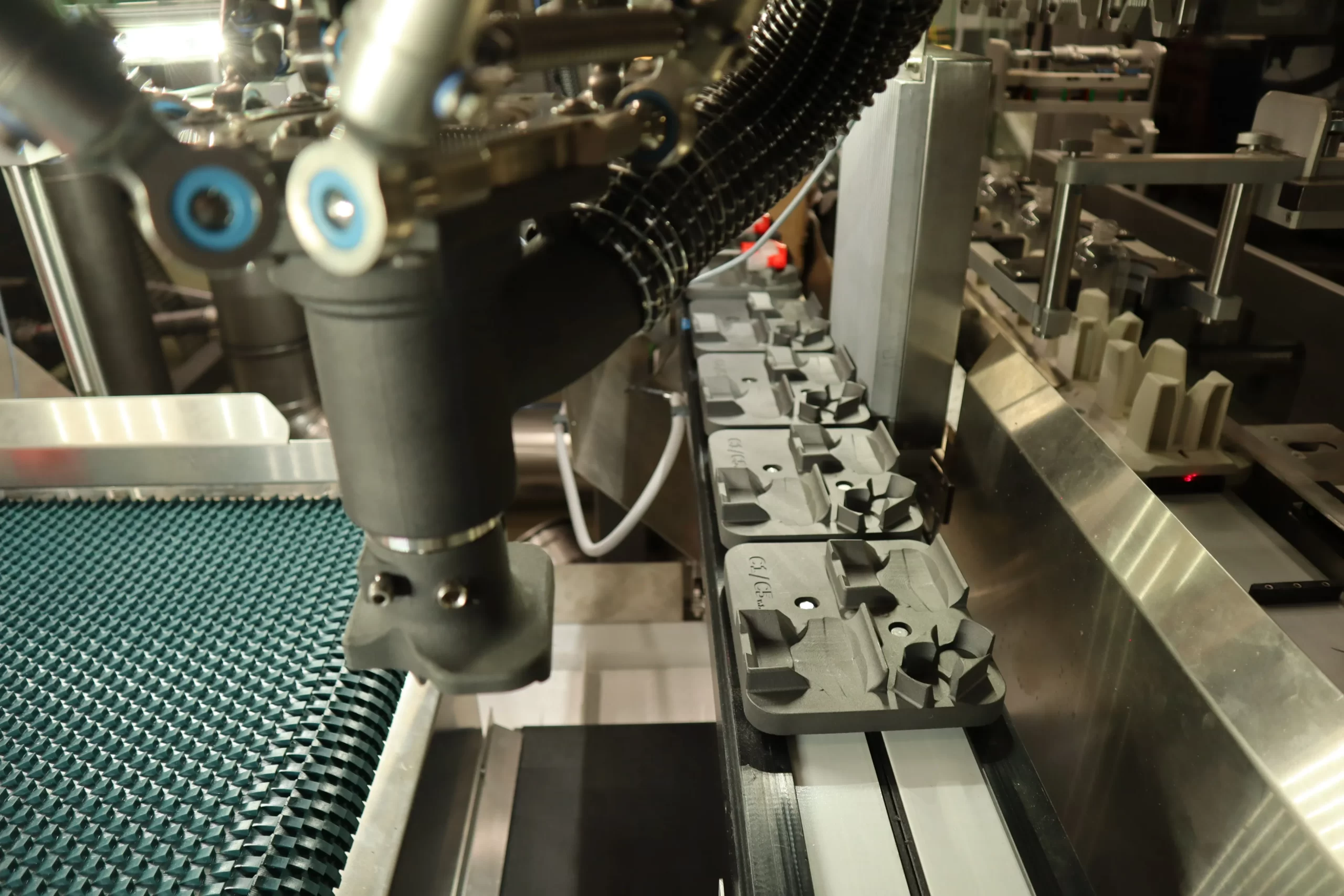

Unilogo’s solutions provide companies with high flexibility in creating formats and, consequently, the ability to adapt production to current needs. Key components of these devices include robotic grippers and so-called format parts, which are small components that adjust the device’s operation to specific bottle sizes, for example.

“From the beginning of our collaboration, we could always count on a partnership approach and a deep understanding of our challenges by the Cubic Inch team. Over the years, our company has evolved, needs have changed, and design support and parts from Cubic Inch have consistently remained an important part of our process. I wish such business partners to everyone.”

Porduct Owner, Unilogo

The production process for Unilogo’s equipment demands flexibility, and time is crucial, especially when modifications are needed to meet individual customer requirements.

To make this process work, equipment parts that meet specific aesthetic and durability requirements are required and must be delivered to Unilogo as quickly as possible. Additionally, some parts required air channels that couldn’t be machined.

3D printing had been considered, and the Unilogo team attempted to print parts using FDM technology. However, these attempts fell short of the strength requirements, and some components couldn’t be printed due to complex geometry.

In summary, Unilogo’s primary part requirements included:

HP Multi Jet Fusion 3D printing technology, which we specialize in, was a perfect fit for these needs. The collaboration began with 3D printing of format parts. From the start, it was clear that the quality of these parts far exceeded those printed using FDM technology.

Over the following months, Unilogo’s team gradually incorporated more 3D-printed elements into their devices, including transport positioners and various types of grips. Each new component led to cost reductions and production process acceleration, as well as increased efficiency and safety – for example, by reducing motor strain through weight reduction.

Importantly, the design capabilities enabled by MJF technology allowed Unilogo to make improvements that were previously not considered. MJF technology enabled the printing of parts with very small threads, eliminating the need for additional assembly. This resulted in significant time savings, especially when producing a larger quantity of such parts.

Mateusz Berk, Product Owner at Unilogo

Based on our experience in designing parts for 3D printing, we provided ongoing feedback to Unilogo’s designers on how to optimize their designs. Suggestions included considerations related to weight, construction, positioning accuracy, and other aspects that could further reduce printing costs or enhance part durability.

At a certain point, the growth in sales and product development became too much for Unilogo’s design team to handle. Therefore, our team provided comprehensive support in this area. We closely collaborated with Unilogo’s designers and engineers during peak periods, designing and optimizing parts for their devices.

We provided the specifications, and the Cubic Inch team designed, printed, and delivered the parts. Having one partner oversee this entire process was very convenient for us.

Our collaboration with Unilogo can be summarized in numbers: dozens of projects, thousands of delivered parts, and hundreds of devices sent to Unilogo’s customers. When we asked Mateusz Berk, Product Owner and Designer at Unilogo, for a testimonial, he pointed out a slightly different aspect:

“From the beginning of our collaboration, we could always count on a partnership approach and a deep understanding of our challenges by the Cubic Inch team. Over the years, our company has evolved, needs have changed, and design support and parts from Cubic Inch have consistently remained an important part of our process. I wish such business partners to everyone.”

3D printing reduced part costs by up to 60% compared to CNC machining.

Unilogo orders are fulfilled within a maximum of 3 days, and sometimes even within 24 hours, due to the lack of shipping.

Quick production of single units significantly accelerated testing and product development for Unilogo.

We provide Unilogo with full support, including consultation, design, and part printing, depending on the company's current needs.