When listing the main arguments for replacing traditional methods of producing parts with 3D printing, the first two benefits are mentioned:

- Savings – in short-series production, the parts’ unit cost can be several hundred% lower.

- Speeding up the process – the ordered parts reach the customer in a few business days instead of several or even a dozen or so weeks.

Issues related to project optimization and using the unique opportunities offered by additive technologies usually fade into the background – at least in the initial stages of discussion.

However, this topic eventually comes to light, and often, changes occur at this stage. They allow us to improve parts and streamline subsequent stages (such as assembly), further reducing costs.

The material below will describe how additive technologies’ unique capabilities help companies quickly implement and optimize projects.

How is designing for 3D printing different from traditional technologies?

It is worth starting the extensive topic of optimizing designs for 3D printing with the term “additive technologies”. This means that parts are created by gradually adding successive layers of material until the desired shape is achieved.

This method differs significantly from traditional solutions, where a mold (e.g. casting or injection) or a larger body (methods based on cutting) are required to create parts. Consequently, designers have much greater freedom in creating geometry.

They are limited only by the material’s characteristics and the printer’s capabilities, which, in the case of advanced devices used in production, such as HP MJF, means precision and quality similar to injection molding.

Due to this, the most significant benefit from the use of additive methods can be achieved when 3D printing is implemented already in the early stages of product development. In this way, designers can consider models from the beginning that would be impossible to produce using other methods.

The process is slightly different in the case of existing projects that were initially created with a different technology in mind. In such a situation, excellent knowledge of additive technologies and knowledge of potential optimization techniques that can improve the project or reduce its implementation cost is of key importance in such a situation.

How do we optimize designs for 3D printing?

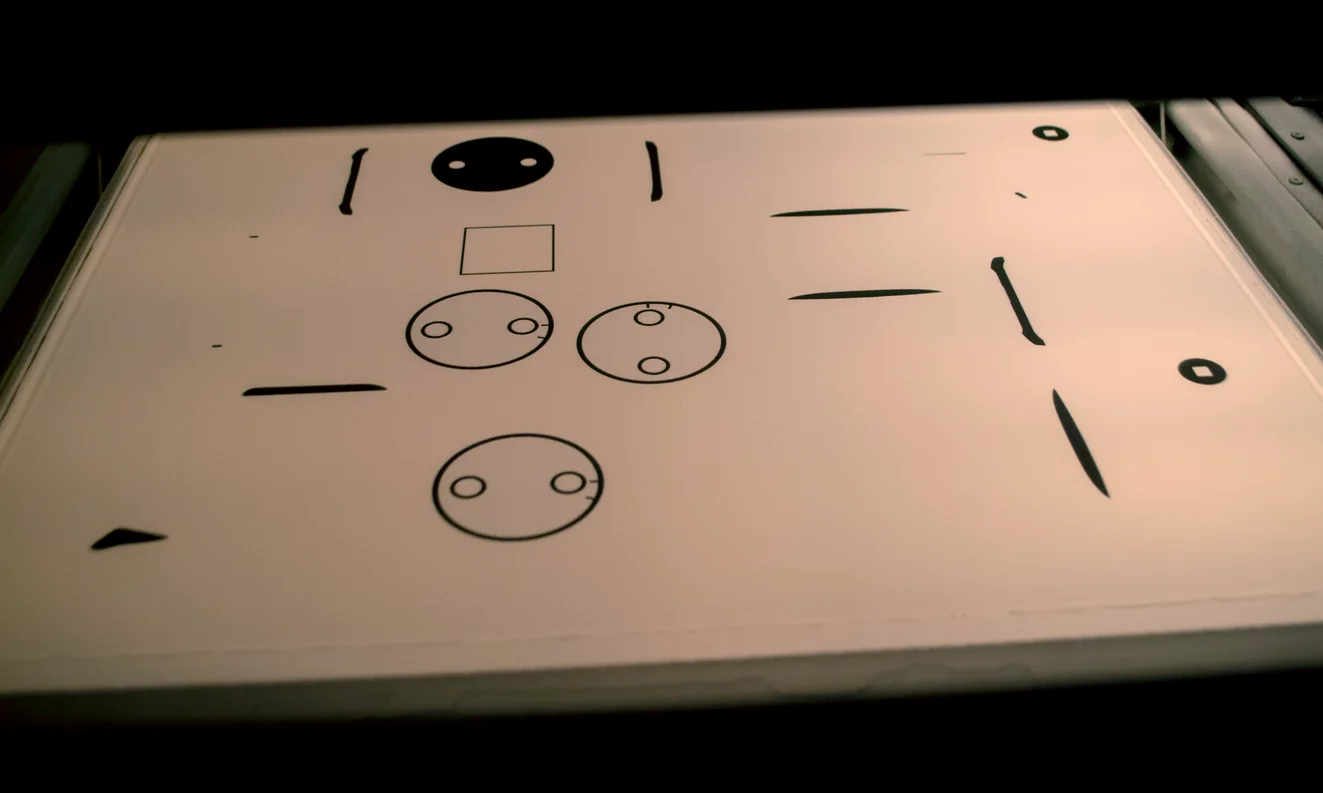

Modifications of designs for 3D printing mainly come down to three methods:

1. Drilling the inside of an element.

- Perfect for large objects that don’t require high mechanical resistance.

- Easy to implement.

- Massive cost reduction.

2. Introducing internal trusses (instead of uniform solids).

- Perfect for large objects that require a decent level of mechanical resistance.

- Relatively easy to implement but requires a proper solution.

3. Topology optimization.

- Perfect for objects with thin walls that are subject to specific load distribution.

- A more complex and time-consuming process that requires understanding an element’s exact purpose.

The first two methods can be performed relatively quickly and substantially reduce weight and, consequently, costs.

Internal trusses are particularly often used because they allow for maintaining very high mechanical strength, and the cost reduction is similar to drilling.

Topology optimization, on the other hand, ensures the most optimal cost/weight reduction while achieving the best mechanical properties of the element. However, this process requires much more time. Importantly, this solution is often the only one possible for thin-walled elements. In such situations, this procedure must be preceded by an analysis confirming the changes’ profitability.

The golden ratio in optimizing designs for 3D printing

Drilling the element is not recommended for walls less than 2-2.5 mm thick. The exact value depends on the size of the part and the function it is to perform – it is necessary to determine it each time empirically.

To achieve the best compromise between price/weight reduction and mechanical strength, the recommended infill geometry is a hexagon-based pyramid with a cell size of 8 mm and a wall thickness of 1.2 mm.

Even despite the lack of limitations mentioned earlier, elements in terms of volume are also worth optimizing in some cases in order to achieve the best possible quality, durability and repeatability.

Ultimately, we reach the golden mean in optimizing projects for the Multi Jet Fusion technology based on experience, a thorough understanding of the project requirements, and the use of knowledge and proven solutions.

What do we achieve by introducing changes to designs for 3D printing?

In most cases, the purpose of the above changes is to “lighten” the original designs while maintaining all functionality and durability features. This is important because one of the key factors influencing the price of printing is the volume of the part.

In many cases, it may be impossible to produce the part without weight reduction due to the high cost. For example, one of our clients sent us an element for implementation that had already undergone partial changes to include production in additive technologies.

However, they did not specifically take into account the Multi Jet Fusion technology, so before we submitted the project to production, we carried out several treatments to further slim down the element. Thanks to them, we reduced the volume of parts by as much as 80%, significantly reducing the final quote for the customer.

Therefore, large elements with uniform filling (solids) are the best candidates for implementing design changes.

What types of parts are most worth optimizing?

Our experience of working with additive technologies shows that approximately 60% of projects can be optimized, improving their functionality or reducing the implementation cost.

Importantly, in many cases, it is even profitable to modify projects that were initially designed using FDM technology. Due to the greater precision and lack of supports in the MJF technology, significant savings can still be achieved in such a situation.

Three key aspects to consider are:

- Element volume to surface ratio: In the case of large-volume solids, the potential cost and weight savings are the greatest, and we will often use all the methods mentioned. The exception will be parts with thin walls, where additional slimming may be difficult or impossible.

- Item Size: The larger the element, the greater the chance that optimization methods will bring large savings, and vice versa for smaller-sized elements.

- Production quantity: As the number of parts ordered increases, the importance of every change, even a small one, increases. In the case of several hundred pieces or regular orders, the introduction of seemingly insignificant changes may have a noticeable impact on the valuation.

What does the process of introducing changes to the project look like?

After receiving the project from the client, we always first verify whether it is possible to implement and whether any optimizations are potentially possible.

In many cases, if a given element was not designed for 3D printing, it is immediately clear that such optimizations will not only be possible but also very profitable for the client.

We always consult the changes introduced with the client’s team, and if necessary, we print test samples before the final print.

Thanks to experience from several hundred projects adapted to the Multi Jet Fusion technology, the process is efficient, and the optimized parts maintain the full range of intended strength characteristics.

If you are wondering whether your project can be implemented with the help of MJF technology, schedule a free consultation.