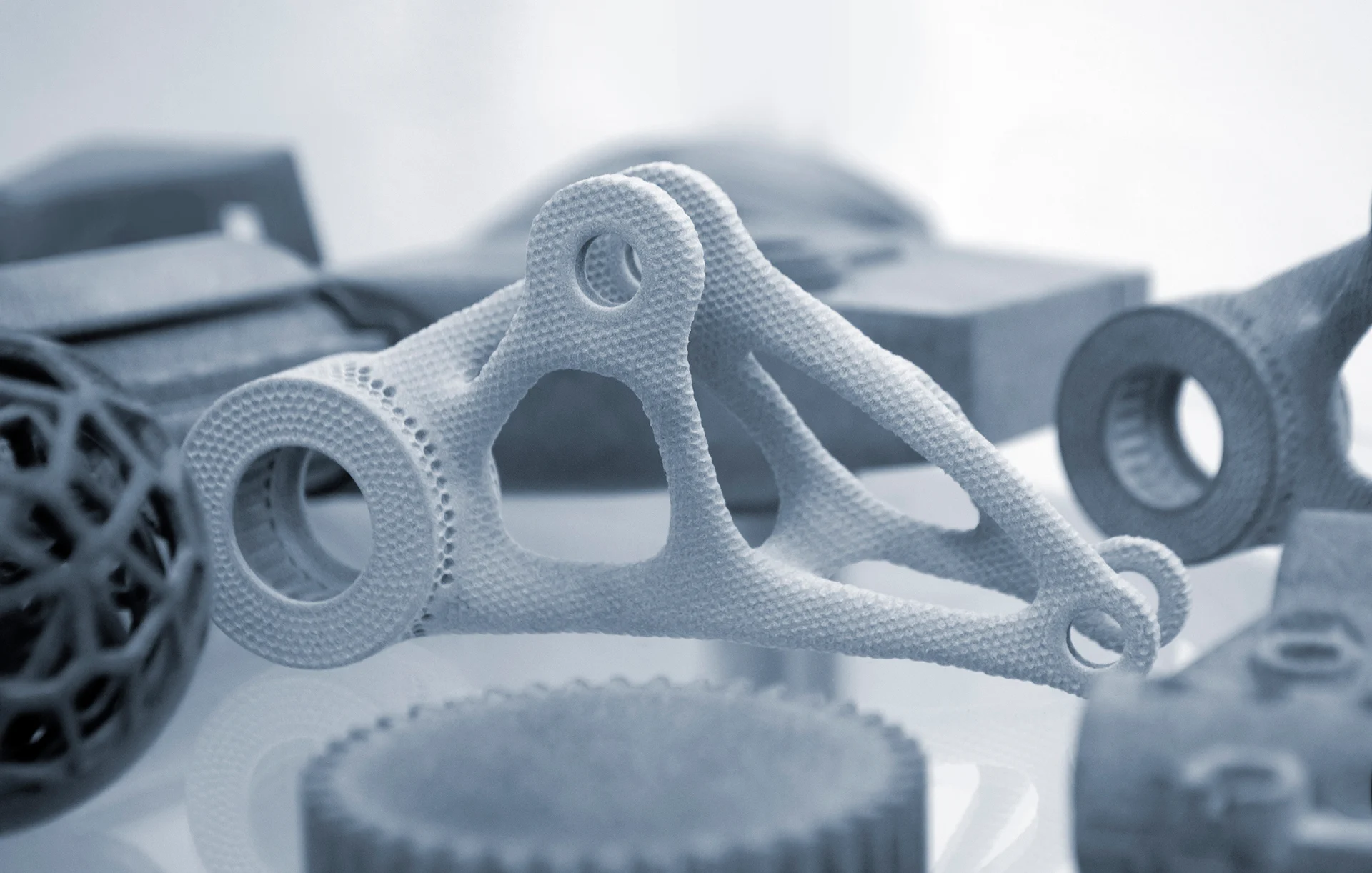

Design for Additive Manufacturing (DfAM) is an approach in which additive manufacturing (e.g., 3D printing) is the default manufacturing technology. Unlike traditional manufacturing methods (e.g., injection molding), additive technologies offer designers broader options in terms of geometry, topology, and a number of other benefits.

DfAM opens the door to designing lightweight yet durable components, creating complex internal structures, and implementing topological optimizations that were previously unattainable or too expensive.

In the context of HP Multi Jet Fusion (MJF) technology, the DfAM approach is becoming even more important. MJF enables the rapid and repeatable production of high-precision parts, and designing for this technology allows for maximum utilization of its potential – from personalization, through weight reduction, to lower production costs.

DfAM vs. Traditional Design Approaches

When designing for injection molding or machining, engineers must consider the constraints imposed by molds, tools, and easily machined geometry. In practice, this means avoiding complex shapes, undercuts, or internal structures—unless someone is willing to pay for very expensive molds or multi-stage processes.

DfAM reverses this logic. Here, the designer doesn’t think about how to bypass the limitations of technology, but how to take advantage of its possibilities. Multi Jet Fusion allows you to print components that combine multiple functions, have complex interiors, or unique surface structures – all in one, fast process.

Here are some of the key benefits of the DfAM approach.

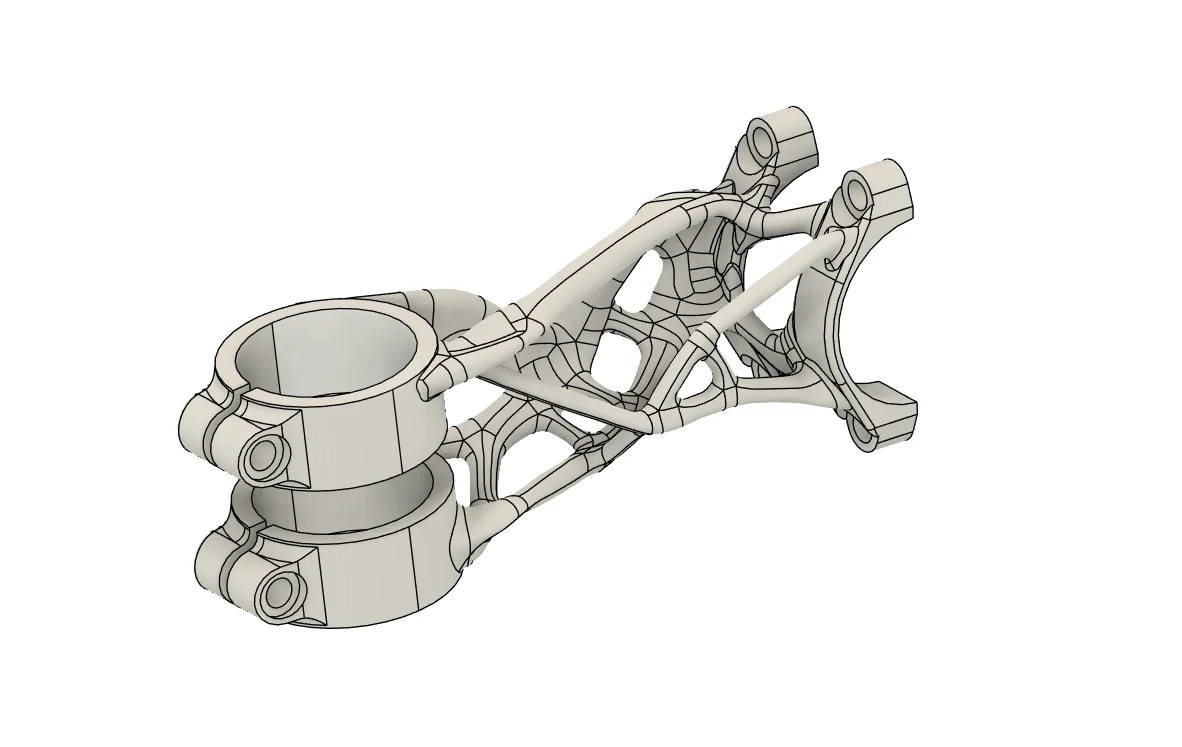

1. Topological optimizations

One of DfAM’s greatest advantages is the ability to implement topological optimization. Computer algorithms analyze the distribution of forces and stresses and then “suggest” a shape that provides strength with minimal material consumption. In the case of MJF, such organic, irregular shapes can be realized without additional costs or constraints. The result? Lighter, cheaper, and more ecological products.

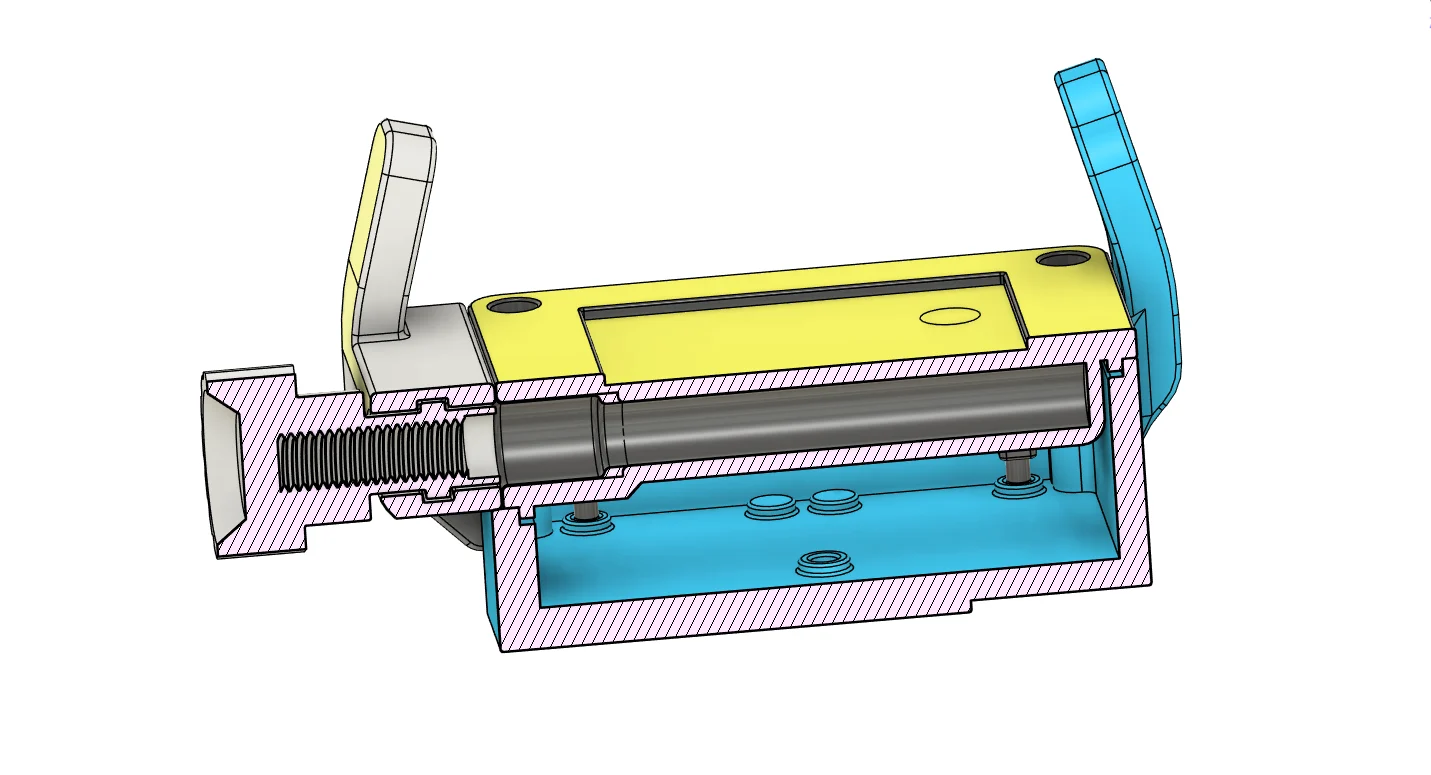

2. Possibility to create combined structures

In traditional manufacturing, many parts often need to be assembled into one unit—which means extra steps, time, and potential errors. DfAM allows integration of several elements into one component, eliminating the need for screws, adhesives, or welds. Thanks to MJF technology, engineers can create things like hinges and complex mechanisms directly during printing.

An example of such a solution is the handle in the device we created for Taxus IT. The mounting bracket shown in the photo (top) was designed to ensure complete stability and simplify assembly as much as possible. This significantly streamlined the subsequent stages of device creation.

3. Limitless iterations at no extra cost

One of the most revolutionary aspects of DfAM is that each print may be different, and the production cost remains virtually the same. In traditional methods – such as injection molding – each geometry change means a new, expensive mold. With Multi Jet Fusion, the difference between a batch of 100 identical parts and 100 parts differing in detail is almost nonexistent.

Let’s take the example of a company specializing in drones. Thanks to the DfAM approach and MJF technology, it can design and manufacture very similar, yet minimally different, devices for specific applications:

- agricultural drones with handles and tanks adapted for spraying,

- rescue drones with space for a first aid kit, thermal imaging cameras and a drop system,

- inspection drones equipped with special mounts for high-resolution sensors and cameras.

Traditional manufacturing would require creating separate molds and assembly lines for each variant. With DfAM, product differentiation is a matter of changing the CAD file—without investing in expensive infrastructure. This not only speeds up time-to-market but also provides a competitive advantage in the form of mass personalization and dynamic response to customer needs.

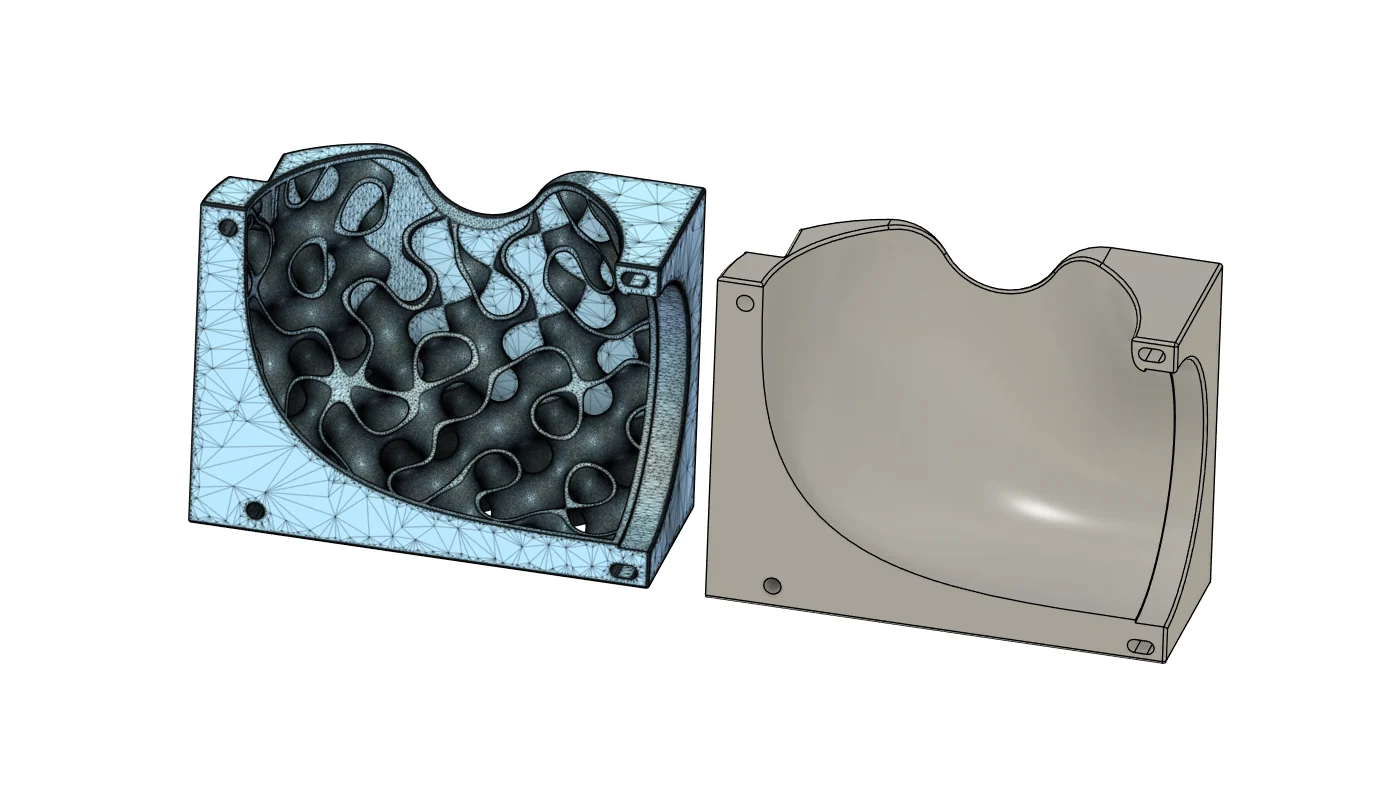

4. Lattice and internal structures

Multi Jet Fusion allows you to print items from lattice interiors– lightweight, yet extremely durable. This allows designers to create components that meet mechanical requirements while being lighter and using less material. Furthermore, these structures can be customized for a variety of functions: from vibration damping and shock absorption to better air and fluid flow management.

These types of solutions are used whenever possible because they allow for reducing the cost of the project while maintaining strength and mechanical properties. In some cases, it is possible to reduce the weight of parts by more than 30%.

The topic of lattice structures and other design optimizations for 3D printing is described in detail in the article:

From traditional methods to HP Multi Jet Fusion – optimizing designs for 3D printing

How to Change Your Design Approach to DfAM?

Before we begin to fully utilize the potential of additive technologies, it’s important to first understand their limitations. This is the starting point for effective DfAM design.

It is worth noting that each 3D printing technology has slightly different characteristics. Printers differ in material feeding methods, curing methods and many other aspects that influence the final effect.

In the case of Multi Jet Fusion technology, we need to pay special attention to:

- Designing large, flat elements – may deform during printing and cooling.

- Long, thin shapes – are susceptible to bending and cracking.

- Too thin walls or delicate details – may be damaged during printing or post-processing.

- No post-processing taken into account – processes such as sandblasting, grinding or dyeing require an appropriate supply of material and access to the surface – they can, for example, smooth out sharp angles.

- Too tight fits – elements requiring high precision should be printed separately and adjusted after printing.

Knowing these limitations, you can effectively start using the advantages of 3D printing and apply the solutions mentioned in the article.

Finally, remember that we don’t have to start from scratch. There are many databases of ready-made designs and active design communities from which we can draw inspiration, learn design solutions, and analyze examples of best practices.

Great places to explore are platforms like Cults3D, MakerWorld or GrabCAD. They provide a great way to understand how other designers are using the power of additive technologies – and to more quickly develop your own design style for 3D printing.