Small 3D printers based on FDM technology are an integral part of the process, especially in the early stages of design. Thanks to them, R&D departments can easily create models allowing for basic tests.

However, this common technology has significant imperfections. Parts created on FDM printers have visible layers, are often inaccurate, and do not allow for detailed tests due to the lack of appropriate strength and isotropy.

To solve this problem, you should look for other technologies, e.g. HP Multi Jet Fusion. This additive technology, created in 2016, allows companies to quickly and cost-effectively create high-quality prototypes, and at a later stage, also serial production of these parts.

As manufacturers of innovative devices are increasingly discovering, this possibility has a revolutionary impact on the entire process of introducing new products to the market.

How do FDM-printed prototypes slow down the product development process?

FDM (Fused Deposition Modeling) technology, despite its popularity, easy availability, and low cost, has significant imperfections that may hinder the product development process.

Firstly, FDM prints are characterized by relatively low precision and visible layer structure, which significantly limits the possibility of a realistic assessment of the aesthetics of the designed product. The surfaces are often rough and require additional processing, and even then, it is difficult to achieve a quality similar to the final product.

Another limitation is the low mechanical strength of parts printed using FDM technology. Due to the way the material is applied, these elements are particularly susceptible to cracking along the layer lines and do not reproduce the mechanical properties of similar parts created using other technologies. As a result, it is difficult to reliably test the prototype in terms of durability, flexibility, or resistance to operating conditions.

As a result, although FDM enables quick and cheap creation of initial conceptual models, it may slow down product development at later stages, especially when a realistic assessment of the appearance, ergonomics, or functionality of the prototype is needed.

In short, they do not reflect the quality of the finished product, which may lead to incorrect conclusions and the need to repeat subsequent design iterations using more advanced technologies. In the end, these “quickly” prototypes end up prolonging the entire process.

To summarize, the most important problems associated with FDM prototypes are:

- Aesthetic defects and visible filament layers.

- Low precision and repeatability of printing.

- Low mechanical strength and lack of isotropy.

Multi Jet Fusion: prototyping and production in one solution

Created by HP in 2016, Multi Jet Fusion (MJF) technology is an advanced and highly effective alternative to FDM, eliminating many of the limitations of this popular but basic 3D printing method.

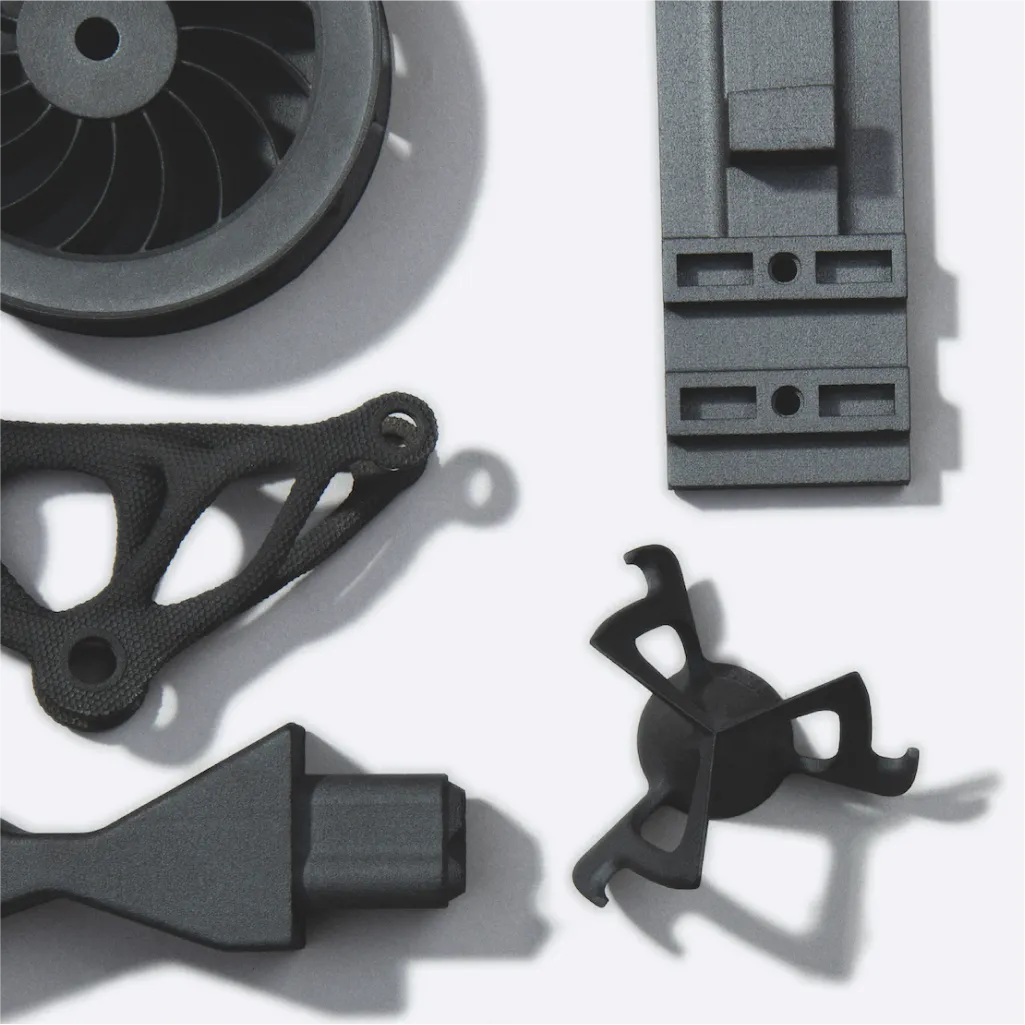

Unlike FDM, it was created not only for the creation of prototypes, but also for short and medium series production. Instead of filament, parts are sintered from powder, without the need to use supports, and up to several hundred elements can be created in one process.

Thanks to its precision, durability, and high-quality surface, MJF allows you to create fully functional prototypes that faithfully reproduce both the appearance and mechanical properties of the final products.

This is how many of our clients introduce new solutions to the market. In our materials about cooperation with companies such as Perun Airsoft or Taxus IT, you will read about how prototyping and production of parts using the same technology has become an integral, extremely valuable element of the current process of introducing products to the market.

The above case studies do not omit the key aspect that always plays a role in such processes, that is, of course, prices. When it comes down to it, MJF technology is the perfect alternative to injection molding, especially when the company does not plan mass production, but only a series of several hundred or several thousand pieces.

Without the need to invest in expensive injection molds, it is possible to quickly start production and flexibly introduce design changes according to market needs, without losing quality and efficiency.

To sum up, Multi Jet Fusion is a technology that combines the advantages of rapid prototyping with the possibilities of low-volume production, providing real support in the modern product development process.

FDM and MJF – symbiosis, not competition

It’s worth emphasizing that FDM and MJF can perfectly complement each other at various stages of product development.

Most of our clients still use FDM printers at the early design stage, when it is important to quickly and cheaply produce conceptual models for initial design assessment. This is a stage where high mechanical properties or perfect aesthetics are not yet required.

Only in subsequent phases, when the product is approaching its final form and it becomes necessary to test its functionality, durability, and appearance, companies turn to us.

With our solution, they can create accurate and realistic prototypes and then smoothly transition to short-series production without changing technology.

This division of roles allows you to optimize the costs and time of product development, using the strengths of each technology where they work best.

So if you feel that functional testing is something missing in your process, contact us.