3D printing and injection molding are technologies that have been considered fundamentally different in terms of application for years. 3D printing was associated only with prototyping, while injection molding had (and still has) a firmly established status as the best technology for producing plastic parts, with one significant drawback: a very high initial cost.

However, this industry status quo changed a few years ago due to the appearance of large 3D printers called HP Multi Jet Fusion. These devices were created with a clear intention – to enable cost-effective short-series production of high-quality plastic parts.

Financial and technological blockers of injection technology

While injection molding is perfect for mass production, is associated with high initial costs, mainly due to the need to create an injection mold. The cost can rise to €100,000, so for some companies, this is an impossible barrier to overcome, not to mention the long waiting time for the form.

This cost is particularly problematic for companies designing innovative devices just waiting to hit the market. Such an investment is usually far too risky for a manufacturer who wants to release a series of approximately 500-1000 devices initially. An additional problem in the case of such projects is that once made, the mold may be impossible to modify, which means that any changes to the design will be impossible.

As a result, injection molding, perfect in terms of quality and precision, has been unavailable to many startups, factories, and various types of device manufacturers.

As an alternative, slightly cheaper vacuum forming, CNC cutting was used, and in the case of very small quantities, even 3D printing using FDM or SLS technology.

However, there was still a lack of ideal technology for such projects. And the creators of HP Multi Jet Fusion – 3D printers designed specifically for production – were undoubtedly aware.

How does Multi Jet Fusion solve the problems of injection technology?

By releasing MJF printers, HP gave the industry a clear signal – these machines were created to fill this problematic niche.

It was clear from the beginning that the parts created at MJF were characterized by:

- high repeatability

- precision, even in the case of complex geometries

- high strength, the same on each axis

- aesthetics

With these characteristics alone, these devices could automatically become a leader in the category of additive technologies. However, the key differentiator was their significantly higher efficiency than competing solutions. During one process, they produce up to several hundred parts without initial costs, opening up new opportunities for companies.

Instead of investing in a very expensive injection mold, we can simply 3D print the parts, obtaining elements of comparable quality much faster and at a lower cost. What’s more, we can order subsequent batches on-demand, according to demand, without having to freeze funds.

Our client, Cortivision, had this exact challenge. The company creating an innovative device for testing brain activity needed a technology that would meet stringent quality requirements and allow for the profitable release of the first series of the product.

However, the manufacturer was aware that at a later stage of development, the product would be ready for larger production runs. At that point, injection technology would become a more profitable solution. Initially, 3D printing was a great solution, but as demand increases, injection molding is often the endgame in the product’s lifecycle.

The profitability threshold of 3D printing in production

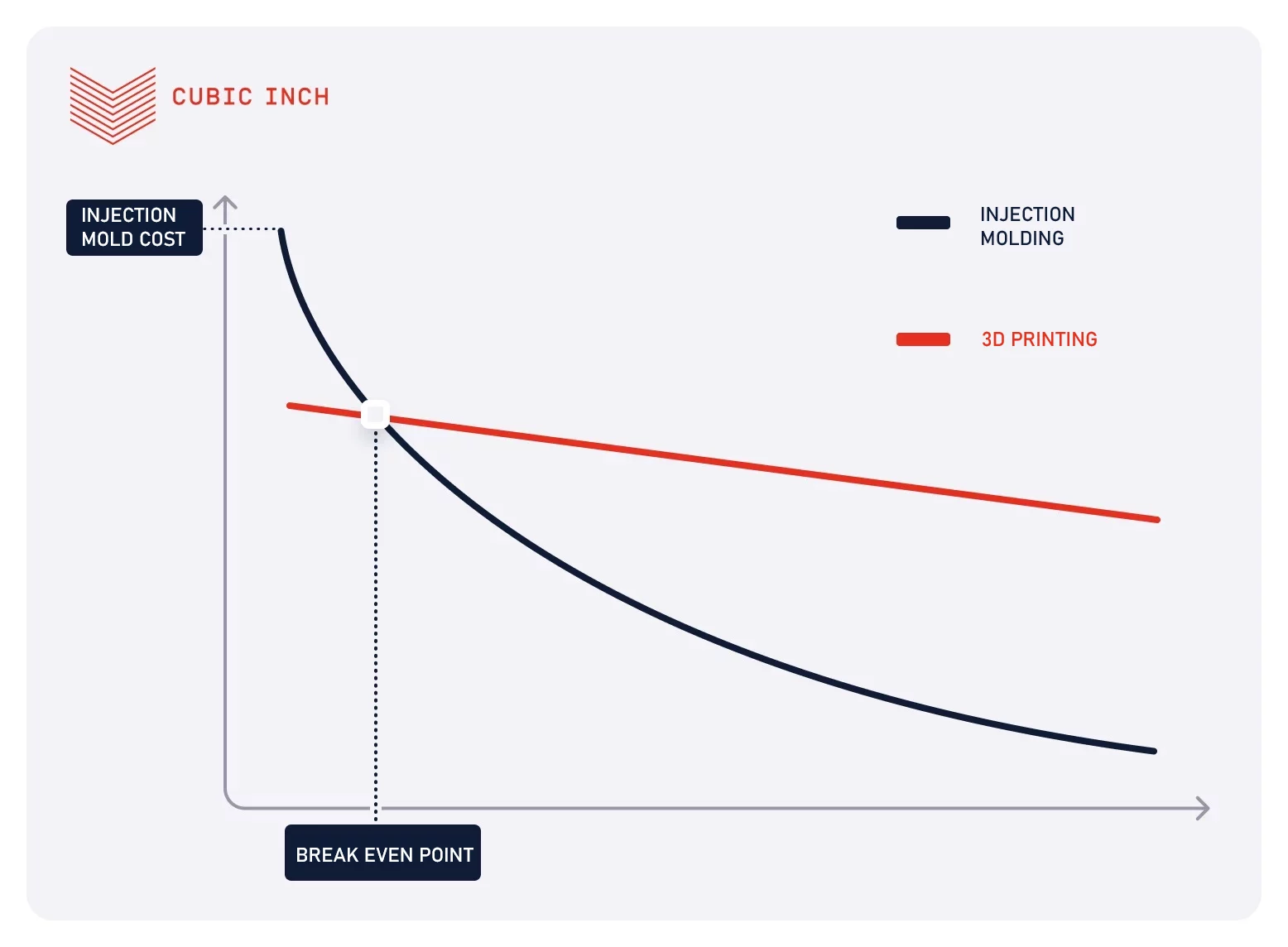

The break-even dilemma boils down to the chart below:

Simply put, it comes down to calculating:

- At what volume is it profitable to print parts in MJF

- At what volume does injection technology become more profitable

So let’s assume that in the case of an example housing for a device, the cost of making an injection mold would be PLN 40,000 and printing PLN 40. We ignore the cost of the injection itself in the context, because compared to making the mold it is marginal.

Transferring the numbers to a chart, it looks like this:

40000:40 = 1000

This means that the break-even point in this situation is 1,000 units. With this number of parts, it will be more profitable to invest in an injection mold.

Of course, we are talking here about the issue of profitability alone, without taking into account many other factors that companies must take into account when making decisions about the choice of technology, which we describe in the table below:

Injection technology | Print 3D HP Multi Jet Fusion | |

Possibility to change the design between series | Very expensive or impossible | No additional costs |

Delivery time of the first parts | Even a few months after ordering the injection mold | From 3 to 5 days |

Investment | Cost of injection mold | Zero PLN |

Possibility to scale production | Easy and cheap | There is no scale effect |

The final decision on the choice of technology should always take into account the above variables, but as we observe from an increasing number of our clients, these solutions are increasingly understood not as competitive but as ideal tools at various stages of product development.

3D printing in MJF technology becomes the default technology in the prototyping and production phase of the first series, and injection molding is the target solution when the product already achieves sufficient sales forecasts.

If your project is at this first stage, please write to us. We will be happy to help you move on to the next one 🙂