The last thing we need in an emergency is someone saying the extremely helpful and necessary words:

“I told you so.”

Oh no. We need solutions, and fast. Especially if the issue concerns the lack of necessary tools, format parts, and other elements necessary to maintain operations, continue production, or release the product to the market.

In the case of precisely made plastic elements, 3D printing may be a solution. That’s how we came across a device manufacturer that needed only a small cable cover to obtain CE certification.

There is one element missing to finalize the project, and it is needed immediately

The only thing standing in the way of the premiere of our client’s device was obtaining CE certification, which was not possible without a small part – the cable cover.

The absence of this key element meant that the entire process had to be stopped. Orders cannot be finalized and the large funds invested in the production of the devices are therefore frozen until the problem is resolved. The longer this situation persists, the more severe the consequences become.

An additional problem was that not only were there no cable covers, but they were also not included in the design whatsoever.

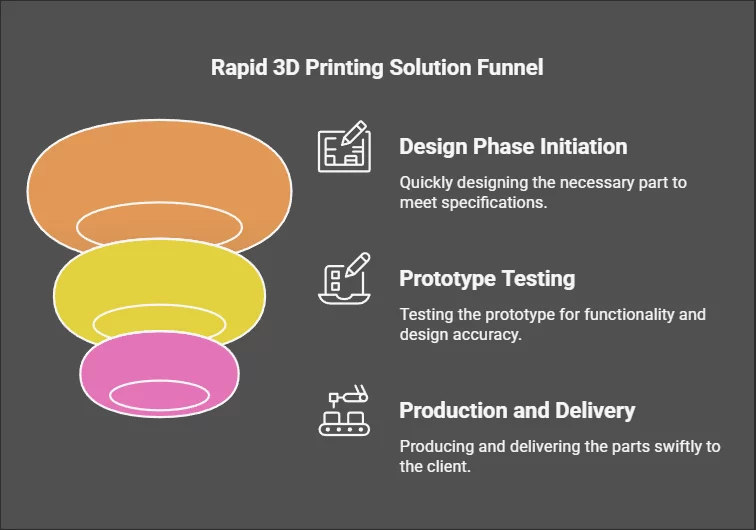

So when the client came to us, we implemented an express mode, which included both the design of the element as well as production and delivery.

The design stage was completed in X days. We analyzed the existing design and selected a perfectly fitting, light, and durable solution that meets the criteria necessary to obtain certification.

In the next step, we sent the client a fully functional prototype, which was tested, and after cosmetic corrections, we received the green light for production. First batch It was delivered to the customer within 5 business days of the order.

Due to the efficient process and attractive price, the client decided to enter into long-term cooperation with us. Over the following months, we delivered tens of thousands of elements according to the current demand.

This situation is one of many similar ones. Our service first becomes a lifeline and shortly thereafter becomes permanently included in the process.

What exactly makes 3D printing using MJF technology so perfectly complements modern production processes and implementation of innovative projects?

- High quality and repeatability of parts similar to injection technology

- Easy availability of parts and the ability to quickly process orders within a few business days

- The possibility to freely change the design between series – especially appreciated by manufacturers of new devices

What other situations cause parts to be needed “right now”?

Unexpected design changes and the need to order additional parts are just one possible reason why a company urgently needs new parts.

Each year, global supply chains encounter new challenges that delay or even disable existing solutions for companies that rely on their stability. The main factors include:

- Armed conflicts,

- Embargoes and consequences of international agreements

- Global port congestion

- Natural disasters

- Shortages of key raw materials

- and many others

In the latest blog article we describe the role of 3D printing in eliminating risks for the supply chain and the long-term impact of implementing this solution into an ongoing process.

Will 3D printing also work for you?

If you are wondering whether, in your case, parts created using Multi Jet Fusion technology will effectively replace those created using other technologies, we will be happy to answer all your questions and create functional prototypes that will help you 100% verify the solution.

Make an appointment for a consultation.