A 3D printer is an expense that every company can afford. Of course, only as long as we’re talking about the devices based on FDM technology, which are intended primarily for the production of single parts and prototypes.

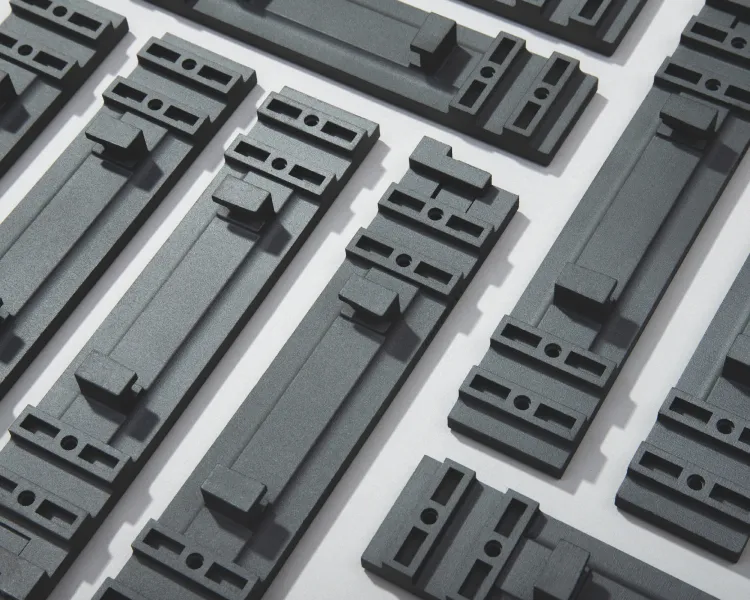

However, additive technologies with completely different applications have been available on the market for several years. With devices such as HP Multi Jet Fusion, 3D printing is used in the mass production of parts, tools, housings, and other plastic elements.

More and more companies requiring constant supplies of parts are considering investing in such equipment. As always in such situations, the question arises: “Will it be worth it?”

Costs of maintaining and operating the production HP Multi Jet Fusion 3D printer

Operation and maintenance of simple desktop 3D printers is cheap.

In the case of large industrial equipment, the situation becomes much more complex. Here are all the costs associated with owning and operating such a printer:

| Category | Cost |

| HP MJF printer (purchase price) | $350,000-$600,000 |

| Leasing | ~$8,000-$12,000/month |

| Service team (min. 2 people) | ~7,000-10,000/month |

| Cost of energy and materials | ~3,000-5,000/month |

We have listed the constant costs. However, this is not all that should be taken into account.

When choosing such a device, you should also remember about additional costs, such as:

- Production area – min. 70 m²

- Cost of external service or equipment for processing manufactured parts (price depends on the required post-processing – sandblasting, dyeing, chemical processing)

There is also an additional cost that is difficult to specify adapting new technology to company processes and training the team in the use and even design specific to this technology.

To sum up, the total monthly cost (assuming leasing) of owning such a device is approximately $18,000-20,000.

Therefore, when considering whether such an investment will be profitable, the most crucial argument will always be the demand for parts. You can estimate that the minimum monthly production to justify having your own printer is approximately 100 kg of parts.

Finally, the potential risk of printer failure is worth mentioning. In the case of MJF devices, they are subject to the manufacturer’s service, but any failures mean necessary and costly downtime. Companies specializing in printing usually have several devices, so there is no such risk.

So, in what situations will such a move make sense from a financial point of view?

When will investing in your own HP MJF 3D printer pay off, and when will outsourcing be a better option?

Considering the above-mentioned costs, you can calculate several key factors that influence the profitability of your own HP Multi Jet Fusion device.

1. Large and regular demand for parts of various shapes

This factor is definitely the most important and is where all considerations about purchasing or leasing such a device should begin. Only in the case of large and regular parts needs will such an investment make sense.

As a guide, we can talk about at least 100 kg of parts per month. However, if these needs concern large volumes of the same parts, it may turn out that injection molding will be more profitable in the long run.

This is because the key advantage of 3D printing is the lack of upfront cost. This allows the production of parts of any shape during one process and the introduction of any changes between series.

However, if a company needs the same parts regularly, the cost of an injection mold may become justified. In our latest blog article, we describe this issue in more detail:

Industrial 3D printing vs. injection molding technology

2. Personalization and production flexibility

Companies that produce a large number of personalized products can benefit significantly from their own printer, but this is still the final argument. Only if you’re manufacturing a large number of custom parts will this investment be viable.

3. Speeding up the process and securing the supply chain

The fact is that your own printer allows for rapid response in the event of failures and sudden parts needs and enables a quick, iterative design and testing process.

In the case of our service, the delivery time is five business days or, in an accelerated, additionally paid process, even three business days, so in most cases, outsourcing will also ensure a very efficient process.

4. Confidentiality and security of project data

For some projects, using external suppliers may be very difficult or impossible – e.g., due to internal security restrictions. In such situations, your printer may be the only solution.

To sum up, having an HP Multi Jet Fusion 3D printer is especially justified in companies that have a significant, regular demand for high-quality parts that need rapid prototyping, production flexibility, and full control over the manufacturing process and quality.

In what types of industries can investing in your printer be profitable?

As in the previous question, the key to answering this question is primarily the high demand and the wide range of parts needed.

Potentially, this solution may prove useful, for example, in the automotive industry, household appliances/electronics, and various types of factories producing consumer goods.

Outsourcing parts production on HP Multi Jet Fusion devices

If your production needs are not high enough to justify an expensive investment in a printer, and you regularly need high-quality parts – preferably quickly, outsourcing will be the ideal solution.

Make an appointment with us for a free consultation, and we will help you determine whether 3D printing will work for your company.