Company

Perun Airsoft

Date

2020-now

Solution

Material

Order sizes

1-1000+ pcs

Delivery time

3-5 business days

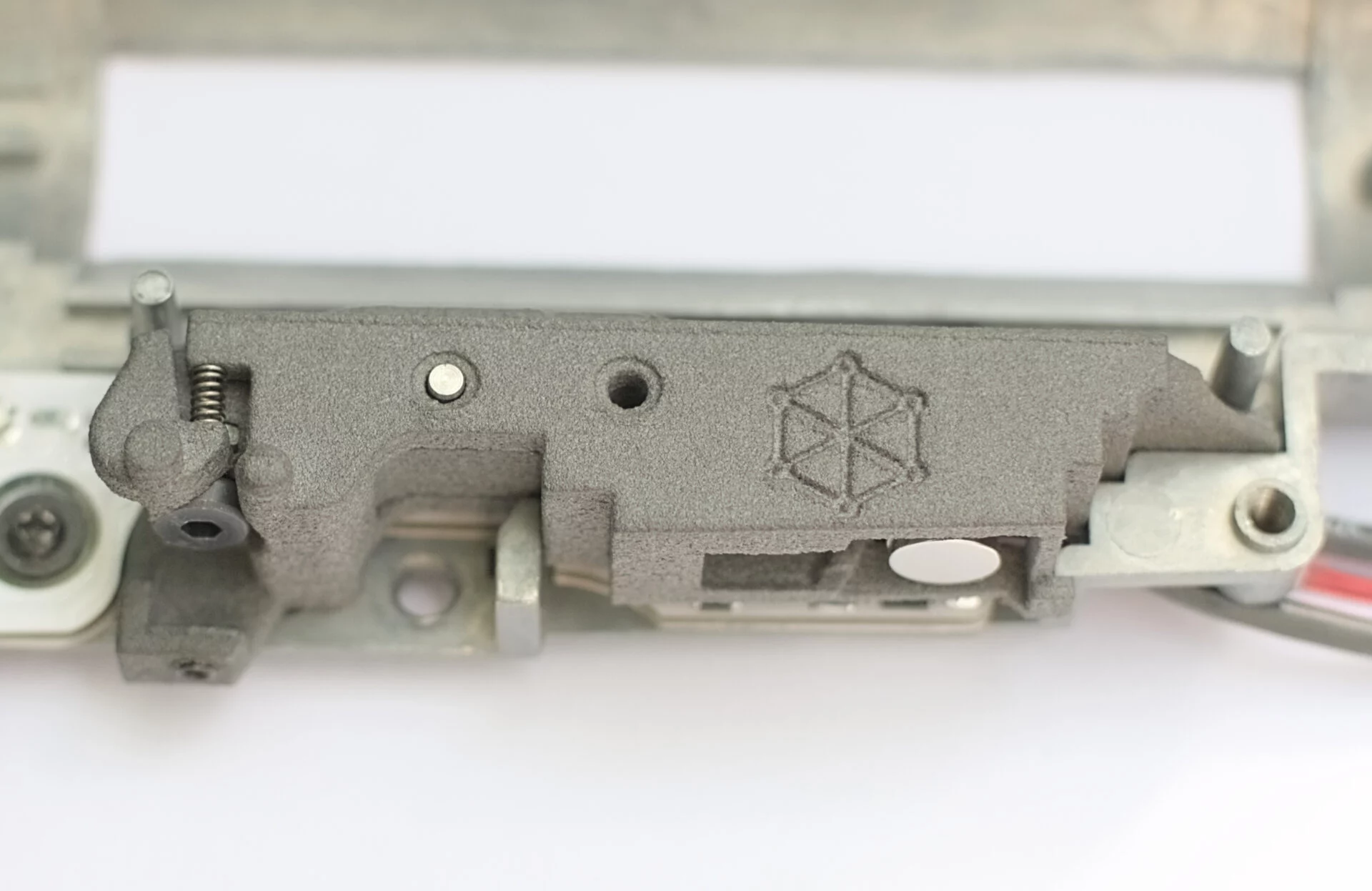

Perun Airsoft is a Polish tech company that creates MOSFET systems and other parts for airsoft replicas. The company’s mission is to provide parts of the highest possible quality that will not disappoint players in the most extreme situations.

“The quality of parts printed at MJF is far ahead of competing technologies, but the process itself and the approach of Cubic Inch as a business partner are also of great value to us. We could not count on such support and quick implementation from companies dealing with e.g. CNC.”

Perun Airsoft Founder

At the beginning of its activity, Perun dealt exclusively with the production of electronics. At some stage, when expanding the offer, there was a need to make parts from plastic.

The key requirements concerned primarily the precision of parts, repeatability, quality and price in the production of short and medium series.

The first technology the client tried was SLA, i.e. resin printing. However, it quickly turned out that the quality of the printed parts was far from the requirements. The pieces were made imprecisely and did not meet the requirements in terms of strength.

After this unsuccessful attempt, the client came to us.

Our cooperation with Perun can be called a model example of the use of MJF technology in the production of devices. It comes down to a few simple steps.

The entire design process is carried out by the Perun team. After completing the work, the client’s designers send us files ready for printing.

We print prototypes of the parts and send them back to the customer for approval.

After verification or possible corrections, we add the projects to the database. At this stage, the customer can place orders immediately or for specific dates.

Already after the first orders, it became clear to the customer that the MJF technology meets all requirements in terms of part quality.

As Jakub Stopyra, the company’s founder, emphasizes:

“3D printing in Multi Jet Fusion technology gives us many possibilities and works great in our application. It is currently the default technology for us and we plan to increasingly expand the number of parts we will produce in this way.”

Cooperation with Perun Airsoft is still developing. Since 2020, we have provided the client with over 10 thousand parts.

Parts printed using MJF technology met all customer requirements in terms of precision and durability.

Low cost of producing parts in volumes even above 1000 pieces without the need for a large investment in an injection mold.

MJF technology allows for any design changes between series at no additional cost.

Szybkie dostawy w czasie 3-5 dni roboczych zmniejszyły przestoje w produkcji i pozwoliły na sprawniejszą realizację zamówień.

Write to us and quickly quote for the implementation of your project using 3D printing.